IMPROVED 24-12 RSB is the rope developed for maximum safety on-board due to the specified construction engineered for reduced snap-back reaction.

Manufactured from High Tenacity Polyester and the superb NIKA-Steel® fibers (developed by KATRADIS MARINE ROPES INDUSTRY SA), IMPROVED RSB ropes are ideal choice for frequent use in a wide range of applications.

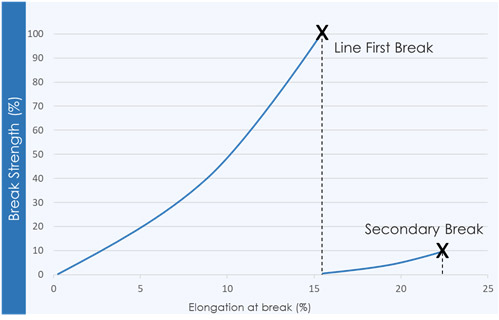

The reduced recoil effect is accomplished with the use of an inner-braid rope structure that will enable the restraining of snap-back release in case of partition. Due to the different elongation properties of the primary rope member and the RSB member, the recoiling of the rope is reduced, which increases the safety on-board.

IMPROVED 24-12 RSB ropes’ layout is ideal for applications requiring floating properties and resistance to abrasion without compromising the axial strength.

They have very good resistance to sunlight & chemicals, good resistance to cyclic loading, and their efficiency remains the same both in wet and dry conditions.

IMPROVED 24-12 RSB ropes are produced according to international standards such as EN ISO 10556. They are user-friendly, rotation-resistant, and easy to splice. They comply with the latest regulations and recommendations of OCIMF for the safe mooring of tankers.

The two-step partition of the rope is attributed to the RSB member that exhibits higher elongation and restraints the extreme snap-back effect when the rope is stretched to break.

| Nom. Size (Diam) |

Nom. Size (Circ) |

Weight (+/- 5%) | MBL (acc. ISO 2307) |

LDBF (acc. MEG4) |

|

|---|---|---|---|---|---|

| mm | inches | kg / 100m mtr | kg / 220 mtr | tn | tn |

| 36 | 4 1/2” | 73.1 | 160.8 | 28.6 | 26.0 |

| 40 | 5” | 85.0 | 187.0 | 35.5 | 32.3 |

| 44 | 5 1/2” | 102.0 | 224.4 | 41.8 | 38.0 |

| 48 | 6” | 121.0 | 266.2 | 49.2 | 44.7 |

| 52 | 6 1/2” | 142.0 | 312.4 | 55.4 | 50.4 |

| 56 | 7” | 162.0 | 356.4 | 64.8 | 58.9 |

| 60 | 7 1/2” | 186.0 | 409.2 | 72.2 | 65.6 |

| 64 | 8” | 217.6 | 478.7 | 82.6 | 75.1 |

| 68 | 8 1/2” | 243.6 | 535.9 | 92.0 | 83.6 |

| 72 | 9” | 269.6 | 593.1 | 102.4 | 93.1 |

| 76 | 9 1/2” | 299.6 | 659.1 | 115.0 | 104.5 |

| 80 | 10” | 330.6 | 727.3 | 125.4 | 114.0 |

| 84 | 10 1/2” | 366.4 | 806.1 | 136.4 | 124.0 |

| 88 | 11” | 397.4 | 874.3 | 150.5 | 136.8 |

LDBF: Line Design Break Force

MBL: Minimum Breaking Load

more sizes available upon request

Subscribe to our newsletter

This website uses cookies to improve user experience. By using our website you consent to all cookies in accordance with our Cookie Policy.