Manufactured for the demands of the shipping industry, NIKA-Siri S12® COVERED RSB ropes combine high strength and increased safety in mooring operations of commercial vessels such as tankers, LNG, LPG vessels, Bulk carriers etc. The human-centered design of the ropes is the key characteristic of the NIKA-Siri S12® COVERED RSB ropes, while maintaining the high performance and very long service lifetime.

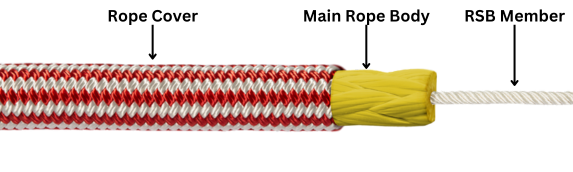

The protective cover offers very good abrasion resistance and gripping properties when used on winches, capstans, and other types of hardware.

Also the cover provides extra protection against abrasion, UV sunlight and environmental degradation. The cover is non-load bearing and repairable with the use of repair kit.

The 12strand core is treated with NikaThane coating and the unique Linear Structural Preformation (LSP) process enhance the fiber’s superior characteristics and improve drastically the structural stability and the strength efficiency of the rope. Also, the NikaThane coating improves the core-cover interaction, minimizing the cover slack during operation.

NIKA-Siri® S12 COVERED RSB ropes are 7-8 times stronger than steel ropes and 3 times stronger than polyester (on a weight by weight comparison). When compared to wire ropes, NIKA-Siri S12® COVERED RSB ropes are stronger (for the same weight), lighter (making them easy and fast to handle), safer to use, and cost-saving (minimum maintenance needs, no greases, faster operating times).

NIKA-Siri S12® COVERED RSB ropes are an excellent wire-rope alternative and some of the reasons are the following:

NIKA-Siri S12® COVERED RSB comply with OCIMF’s latest regulations & recommendations for the safe mooring of commercial vessels.

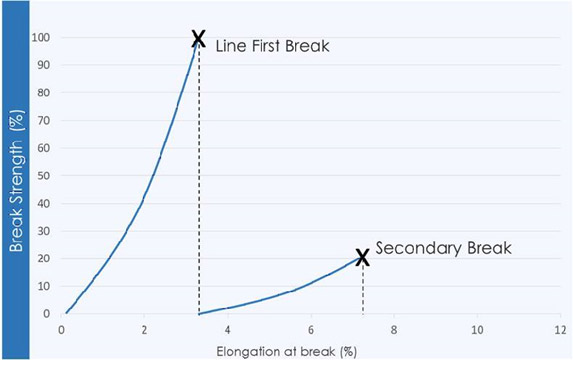

The two-step partition of the rope is attributed to the RSB member that exhibits higher elongation and restraints the snap-back effect when the rope is stretched to break.

| Size (Diam) | Weight | Minimum Breaking Load | LDBF (as per MEG4) | |

|---|---|---|---|---|

| mm | Kilos /100m | Kilos /220m | tn | tn |

| 21 | 36,3 | 79,9 | 36,4 | 33,1 |

| 23 | 45,0 | 98,9 | 45,1 | 41,0 |

| 25 | 49,9 | 109,7 | 52,7 | 47,9 |

| 27 | 56,9 | 125,3 | 61,1 | 55,6 |

| 29 | 76,1 | 167,5 | 71,6 | 65,1 |

| 31 | 81,0 | 178,2 | 80,2 | 72,9 |

| 33 | 85,3 | 187,7 | 87,7 | 79,8 |

| 35 | 88,3 | 194,3 | 93,0 | 84,5 |

| 37 | 94,6 | 208,2 | 104,0 | 94,6 |

| 39 | 107,0 | 235,4 | 117,0 | 106,4 |

| 41 | 146,7 | 322,8 | 132,8 | 120,7 |

| 43 | 153,2 | 337,1 | 144,1 | 131,0 |

| 45 | 168,8 | 371,3 | 159,4 | 144,9 |

| 47 | 177,3 | 390,0 | 174,3 | 158,4 |

| 49 | 207,0 | 455,5 | 193,5 | 175,9 |

| 51 | 216,0 | 475,3 | 209,3 | 190,3 |

| 53 | 229,9 | 505,9 | 228,4 | 207,6 |

| 58 | 258,9 | 569,6 | 242,9 | 220,8 |

| 62 | 282,9 | 622,4 | 283,3 | 257,6 |

| 66 | 312,9 | 688,4 | 298,1 | 271,0 |

LDBF: Line Design Break Force

MBL: Minimum Breaking Load

weight tolerance is +/- 10%

more sizes available upon request

Subscribe to our newsletter

This website uses cookies to improve user experience. By using our website you consent to all cookies in accordance with our Cookie Policy.