Find out how your operations can benefit from HMPE ropes

Traditional rope comparison:

Considering the average lifetime of high Performance ropes which is at least double compared to traditional mooring ropes, the actual cost of high performance ropes can be halved as one would have to buy 2 or more sets of traditional ropes for the same period. See our actual 4-year mooring rope residual life case study

Compared to wire ropes the cost is even lower!

i. High performance (HMPE) ropes, have an abrasion lifetime that can be 4x times than steel wire ropes, making them even more economical in the long run.

ii. They do not need high investment in maintenance lubricants. It is commonly known that wire ropes require a high amount of grease in order to operate properly and this can be a financial burden during the service life of wire ropes. As a rule of thumb, approximately 2% of the wire’s weight is required in grease, compared to High Performance ropes, where lubrication is optional subject to usage and at a much lower cost.

iii. Fewer personnel is required to handle each rope. Due to the high weight of steel wire ropes, operations become more demanding; labour intensive and time-consuming adding the operational cost of wire ropes. On the other hand, High Performance ropes are lighter and easier to handle making the whole berthing and unberthing operation is much faster.

High performance ropes are more cost effective in the long run!

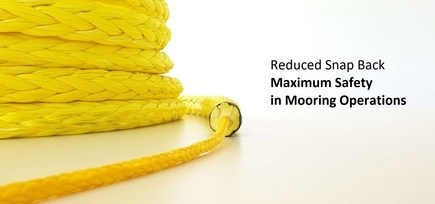

Mooring operation is one of the most important and critical tasks performed on vessels by the seafarers. Securing a ship to a terminal is highly demanding and often entails dangers for crew/ personnel and equipment if safety factors related to mooring ropes are not taken into account. In the serious event of rope partition, an extreme amount of energy is released resulting in a rapid recoiling effect which in many cases can cost human lives.

This is known as the snap-back effect.

Katradis Marine Ropes Industry is always focused in going the extra mile for safety for all types of mooring operations. Siri® High Performance ropes exhibit low elongation properties and lightweight characteristics resulting in much less snap-back reaction in the event of breakage, compared to conventional synthetic mooring ropes and wires.

Katradis Marine Ropes Industry, in its commitment to providing maximum safety in mooring operations, has specifically developed the Reduced Snap Back Siri® High Modulus ropes with minimal snap-back effect. The reduced recoil effect is accomplished with the use of unique inner-braid rope structure that restrains snap-back release in the event of partition. Due to the different elongation properties of the primary rope member and the RSB member, the recoiling of the rope is reduced increasing the safety for the crew involved.

The strength and durability of mooring ropes is critical in demanding operations.

Extensive testing of the Siri® High Performance mooring ropes has shown that they are 7-9 times stronger than steel wire ropes and 3 times stronger than conventional synthetic fiber ropes on a weight by weight comparison.

Chemnitz University of Technology in collaboration with the “Research and Development Unit” of Katradis Marine Ropes Industry has exclusively developed the Siri® Heat-Setting Technology process enhancing the mechanical properties of the rope. The process increases mooring rope performance in terms of abrasion resistance and endurance. The Siri® Heat-Setting process delivers greater strength results even when compared to competitive high modulus ropes.

Siri® Heat-Setting Technology strength enhancement is a two-phase procedure:

Phase a) Coating Process with Polyurethane protective layering upon each fiber increasing abrasion resistance.

Phase b) Heat treatment Designed elongation under specific heat conditions provide a uniform and robust rope structure distributed across the entire rope length.

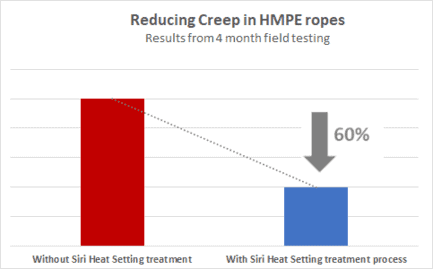

Creep is the permanent elongation of a mooring rope due its usage over time and load bearing. It is the underlying enemy of HMPE mooring lines as it causes a reduction of their service life.

Siri® Heat-Setting process has proven that it can reduce unwanted creep in HMPE mooring ropes. Lab and field tests have shown that the Siri® Heat-Setting process results in a 60% reduction of unwanted creep and an increase in the service life of ropes.

Published by the OCIMF (Oil Companies International Marine Forum), MEG4 represents the best-known mooring practice and reflects the move by the marine industry and regulators towards Human-Centered Design principles. Vessels, fleets and port authorities all over the world are adopting MEG4 guidelines in order to reduce mooring-related incidents which are often the cause of injuries and deaths of seafarers and shore personnel, as well as collisions and property damage.

Katradis Marine Ropes Industry’s commitment to reliability and safety warrant all high-performance ropes meet the requirements of OCIMF for the safe mooring of vessels (tankers, bulk carriers, LNG / LPG, etc.).

Katradis mooring ropes have been successfully tested and approved in accordance with MEG4 specifications and are in compliance with the requirements of OCIMF highest standards.

Katradis is a specialised manufacturer of mooring ropes serving the needs of the marine industry since 1936. With a unique tradition and uncompromising focus in the crafting of mooring ropes, we use the latest high-performance fibres in our products that are available via our international network in over 70 ports across the globe.

Commitment to reliability and quality

With a range of products from mooring ropes to sacrificial anodes, chains, anchors ship deck and port infrastructure equipment, we aim provide safety for the marine industry through the transfer of knowledge and quality products.

10046 Vessels around the world trust Katradis products.

Subscribe to our newsletter

This website uses cookies to improve user experience. By using our website you consent to all cookies in accordance with our Cookie Policy.