Snap back zones are dangerous. Mooring operations are usually one of the most critical activities a ship’s crew needs to perform. Mooring lines keep the vessel tethered to a dock or terminal until the operation is complete. But they may recoil suddenly when they endure severe and unexpected tension causing worker injuries that sometimes may be fatal. If you have been occupied in the maritime industry for some time now, you have probably heard already about snap back zones and incidents associated with them.

If certain safety protocols are not being followed, snap back accidents may happen leading to bone fractures, disfigurement, amputations, crushed limbs, head, neck and brain injuries, back and spinal cord injuries, paralysis or muscle injuries.

Can snap back zones become safer? What can we as manufacturers do to make maritime more human-centered? Let’s dive a little deeper in the matter and search for solid answers.

Areas onboard with a high probability of mooring line recoil are called snap back zones, and of course they are extremely dangerous for your ship’s crew. Failed mooring line ends can snap back wildly with high speed, releasing great amounts of energy and hitting anything standing in their way. This can result in injury or even death to any of your crew members within this recoil zone.

In the past, snap back zones were painted accordingly so they could be easily identified by the staff. Today there is a more up-to-date guideline about snap back zones though. The painting of snap back zones should be avoided because it creates a false sense of security when standing on non-highlighted areas. That can mean only one thing; other measures need to be taken so that personnel security is firmly established.

During an operation and when some parameters cannot be easily managed (i.e. strong winds), too much strain can be placed on a mooring line, causing it to break suddenly releasing violent force. Common causes of such rope failure may be:

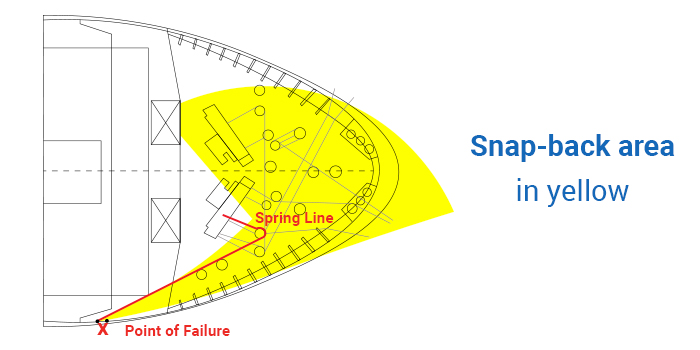

According to latest safety protocols the entire mooring deck should be considered as a potential snap back zone, not only the highlighted parts of the deck. Clear and visible signage must be displayed to warn the ship’s crew about potential dangerous recoiling areas. An example of how snap back zones should be highlighted on a ship’s mooring plan is depicted below:

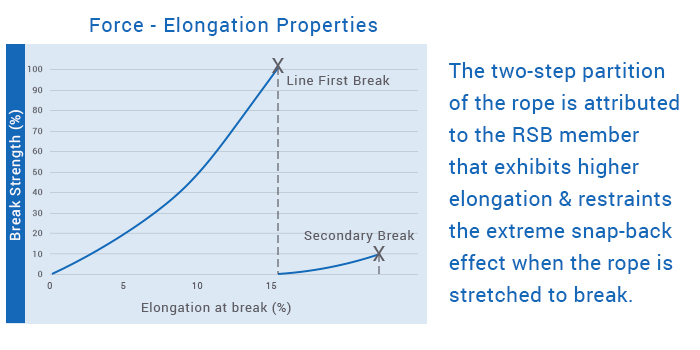

Apart from having a concise description of recoil dangers on deck, MEG4 strongly advises seafarers to use Reduced Snap Back ropes for their operations since these ropes are the latest mooring rope innovation and most safe ropes to use in mooring. They have been developed for maximum safety on deck thanks to the specified properties for reduced snap back behavior.

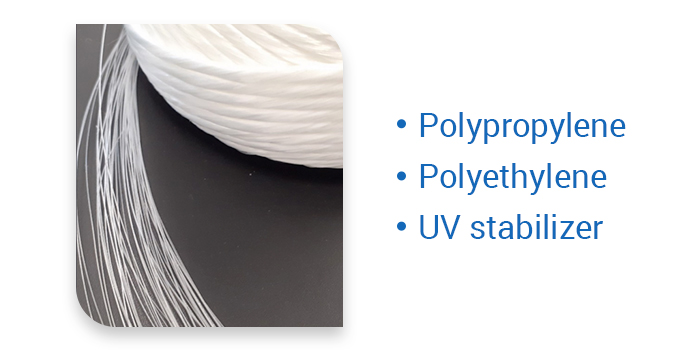

By following international reduced snap back rope testing methods, we have put our NIKA-Steel® fibers to use, and we have developed mooring lines of reduced recoil in a special polymer blend of:

Our research and development team has forged a mixture of superior mechanical properties compared to conventional polypropylene fibers. These properties allow for reduced recoil on a tense rope, giving the ship’s staff valuable time to react and seek safety.

To reassure rope longevity, we add UV stabilization for increased protection against sunlight that normally affects all polymer materials.

Manufactured and certified by international standards our ropes offer reduced recoil effect by their unique inner-braid rope structure that enables the restraining of snap-back release in case of rope partition. They can be used in mooring, anchoring, tow lines and STS operations.

Read more: How to make an eye splice knot: splicing double braided rope step by step

Our RSB ropes:

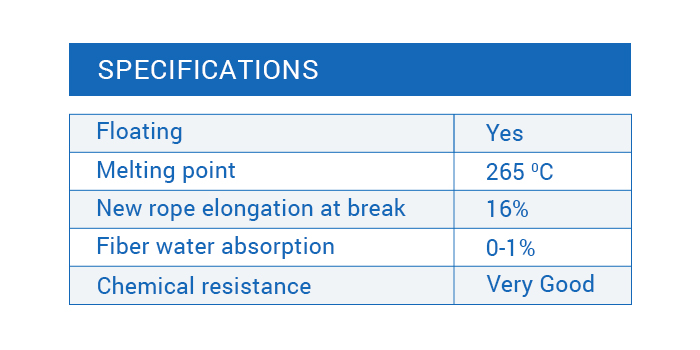

Katradis S.A. RSB rope IMPROVED 24 is the best choice available in the market right now for safer and more efficient operations. Its tenacity resembles the one of wire ropes, yet RSB high performance IMPROVED 24 rope is a clearer and easier in handling rope choice for your ship. The table below shows some brief specifications for our RSB IMPROVED 24 rope.

Using mooring equipment that is properly positioned and secured lies within the risk management responsibilities of the ship owners and ship operators. In any case, it is better to minimize any possible danger that may occur on the ship, rather than having to deal with injuries and damages caused by an accident that could be actually prevented.

Katradis S.A. started in 1936 as a ship supplier specializing in high-quality mooring ropes. Now the company has become a manufacturing expert and a mooring rope pioneer serving the maritime sector globally. More than that, an environmental policy is in place, helping our establishments reduce or even eliminate our carbon footprint.

Follow us on Facebook, Instagram, Twitter and LinkedIn to learn more about us and keep a close eye on our innovative products and testing activities. Contact us and let us know how we can help you in making your ship safer and more environmentally friendly. Our team of experts will answer your questions in no time!