Well-maintained mooring ropes keep the ship and her staff safe. Mooring rope replacement criteria are indications that can help you decide when to replace a worn off rope before it breaks and potentially harms somebody during ship mooring.

Research and testing in various ropes has shown that synthetic fiber ropes have a limited service life. They need to be visually inspected on a regular basis and actively examined, so that they are replaced before failure.

Keeping all safety measures becomes easier when you use equipment of great quality and follow marine industry guidelines, such as MEG4. However, there is no definite way to calculate the exact lifespan of a ship’s mooring gear. Meticulous inspection and maintenance can extend its life service, but decisions about rope retirement still need to be made eventually, and this needs to take place at the right time.

How will you know if that time is now? Which factors affect rope life service, and what can you and the crew do to prolong your ropes’ lifespan without compromising safety? Let’s give some answers to these questions.

The type of the vessel (LNG, bulk carriers, cruise ships etc) defines how often ropes are in use and how heavy their duty may be. In addition, cargo determines greatly the way ropes get affected during an operation. Heavy load, chemicals, grease and dirt can accelerate rope deterioration.

The design of the mooring, the arrangement of the cargo and other parameters regarding everyday on-deck procedures may affect the frequency ropes need to be replaced. Vessel deck equipment and its own maintenance plays an important role as well.

Rusty and gruff chocks and bollards vitiate ropes causing frequent and more urgent rope procurement.

The way you handle and store your mooring ropes will have an impact on their longevity. If ropes are neatly placed around your rollers no serious damage (i.e. twists, compression damage, inconsistent diameter) can occur. Moreover, storing your ropes in clean and dry areas will keep them protected from humidity and chemical failure.

If you’re planning a long operating period, keep in mind that the vessel’s ropes will be used much more than the ones of a vessel planned for a short operating route. This means that your operating pattern is important regarding the condition of the ropes not only at the beginning, but also at the end of your journey. Plan your rope procurement wisely!

Port infrastructure is also something you need to consider. Even if you’ve done an excellent job in maintaining on-deck equipment, ports are someone else’s business to maintain. You need to evaluate the damage to your ropes caused from insufficiently maintained harbor bollards. To be confident your ropes will suffer as little as possible, use rope protective sleeves.

Last but not least, nature and the ever changing weather conditions can affect the mooring gear of a ship. There is not much you can do here, but nature is a parameter you shouldn’t take lightly. If you operate in harsh weather conditions, inspect your ropes regularly, and track historical data to see when each rope needs to be retired.

Research has shown that HMPE ropes have high abrasion resistance and exhibit a strength-to-diameter ratio similar to that of steel wire rope. As rope quality rises, service time gets longer. Katradis quality policy follows all international specifications, offering marine ropes of the highest quality proven by continuous testing within our premises.

MEG4’s mooring rope replacement criteria recommends retiring mooring lines when the residual strength has reached 75% of the Ship Design MBL. But different kinds of ropes wear off at a different pace. Your staff should be able to identify common signs of severe wear off and suggest replacing the damaged ropes in time.

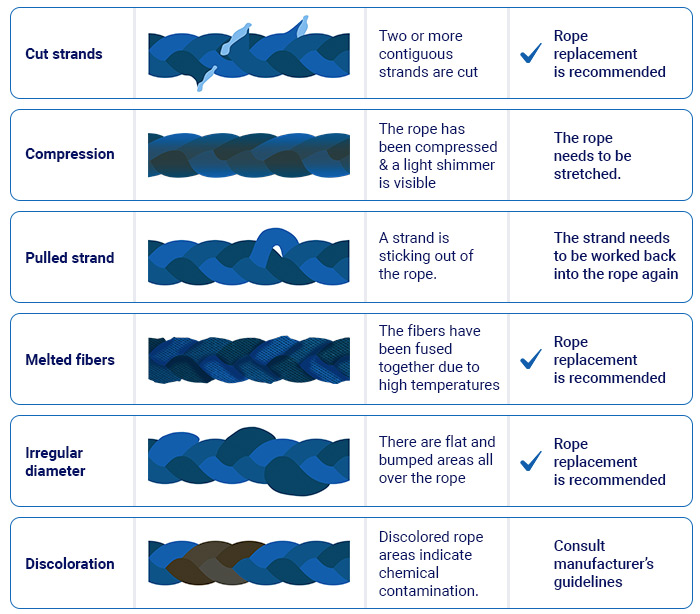

The mooring rope replacement criteria on whether you should repair or remove the rope from service are:

If the damage is in specific areas, the rope can probably be fixed. In other cases and if the rope has undergone serious damage, it should be removed from service for safety reasons. Normal changes such as constructional elongation and splice setting are accepted. Minor pulled strands can be corrected as well, since they pose no threat to rope breakage.

Snap back zones are zones that a rope may recoil under pressure. Even if ropes are newly installed, snap back zones still hold their importance for safety reasons.

Just as wire ropes need maintenance and inspection, the same applies for synthetic ropes. In order to prolong the life of your mooring ropes, there are some routines to set in place that will help you keep your equipment in good condition.

Katradis has developed a software solution for rope inspection. Keep your ropes maintained with tactical inspections with Neptune by Katradis S.A.

Choose a worldwide recognised manufacturer with more than 70 stock points in 4 continents. Follow us on Facebook, Instagram and LinkedIn and keep in touch with us to find perfect solutions for your vessels. Our team of experts will do their best to assist you with your requests.