An offshore mooring system is generally used for keeping a ship attached to a floating platform. Mooring systems are also used by cranes and heavy lifting gear during platform installations. Mooring ropes and wire ropes are used to secure a ship or offshore platform and facilitate activities carried out in the offshore environment such as oil and gas exploration and production, wind energy generation, and marine research.

Mooring ropes play a critical role in ensuring the stability and safety of offshore structures and

vessels, as they prevent them from drifting or moving due to wind, waves, and currents.

The ropes used in offshore applications are typically made of high-strength synthetic fibers such as HMPE (High Modulus Polyethylene) & LCP (Liquid Crystal Polymer) and are designed to withstand harsh marine environments.

Αpart from mooring ropes, a complete mooring system consists of chains, shackles and sockets. Environmental factors like wind, waves and sea currents determine which materials are suitable every time for your vessel’s mooring system.

Fiber ropes for example are used as mooring components in offshore mooring systems, especially in lower temperatures in which wire ropes are unfit to withstand without significant deterioration. Katradis SPECTRA- Siri S12® COVERED rope in particular is the choice for demanding applications which require high durability and lighter weight.

In this article we will be discussing mooring systems in offshore applications, and we will analyze each system type. But first let’s answer some fundamental questions.

The mooring lines preventing sideways motion of a vessel moored to a pier are called breast lines. These lines are vertical to the pier (or at least almost vertical). The mooring design depends on the vessel size, the tides and currents, and other environmental factors (wind strength and direction). In most cases a six-line mooring design can secure the vessel to the pier. For extreme conditions you can ask your rope manufacturer for expert advice on best use practices.

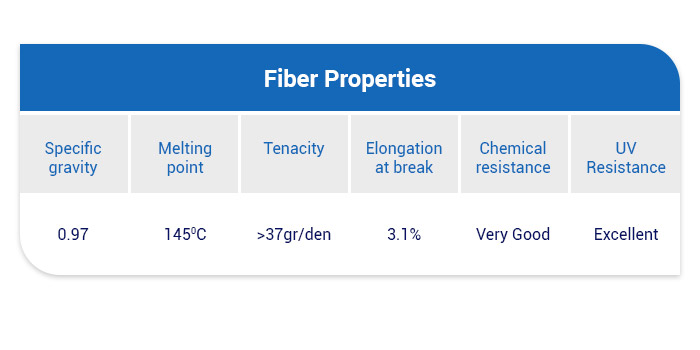

SPECTRA- Siri S12® COVERED ropes is the choice for demanding applications which require high durability and lightweight properties. Supplied by Honeywell (USA), Spectra fibers are widely used in the construction of High-Performance mooring ropes and exhibit inherent advantages compared to other UHMWPE competitive fibers. (UHMWPE: Ultra High Molecular Weight Polyethylene)

There are 6 types of offshore mooring applications. In many of them HMPE ropes are used, offering numerous advantages to the overall subsea installation. Some of them are:

We analyzed how the use of lightweight mooring ropes in offshore applications offers improved

efficiency, reduced operating costs, and improved safety, making it a key consideration for the

maritime industry. The length of mooring ropes is an important consideration in offshore applications as well, as it can significantly impact the safety and stability of the vessel.

The length of the mooring ropes is important for the three following reasons:

Katradis provides customized lengths for mooring ropes according to specific requirements. Renew your vessel equipment today:

Make every offshore application as durable as it can be by using Katradis ropes for your mooring systems. Follow our instructions about wire rope maintenance and read all about the mooring rope replacement criteria. Choose one of our many worldwide stocking points for your inquiries. Learn more about us on Facebook, Instagram and LinkedIn and keep in touch with us for more information about maritime innovative products and solutions.