Over the past few years, the use of High Modulus Ropes (HMPE) in mooring operations of commercial vessels has significantly increased while the operational conditions are getting more and more demanding.

Over the past few years, the use of High Modulus Ropes (HMPE) in mooring operations of commercial vessels has significantly increased while the operational conditions are getting more and more demanding.

Quality and performance is the core parameter for long-term service life and safe mooring operations and this is where our engineering and manufacturing processes make the difference.

Our Linear Structural Preformation (LSP) process which has been developed by KATRADIS MARINE ROPES INDUSTRY SA with mutual studies along with Chemnitz University, is a key stage in manufacturing our Siri High Performance ropes. Basically, it is a two-step procedure which enhances the mechanical properties of the rope:

Residual strength tests from used ropes in the field have shown excellent results which verify the high quality and long lifetime expectancy of our Siri® High Performance ropes.

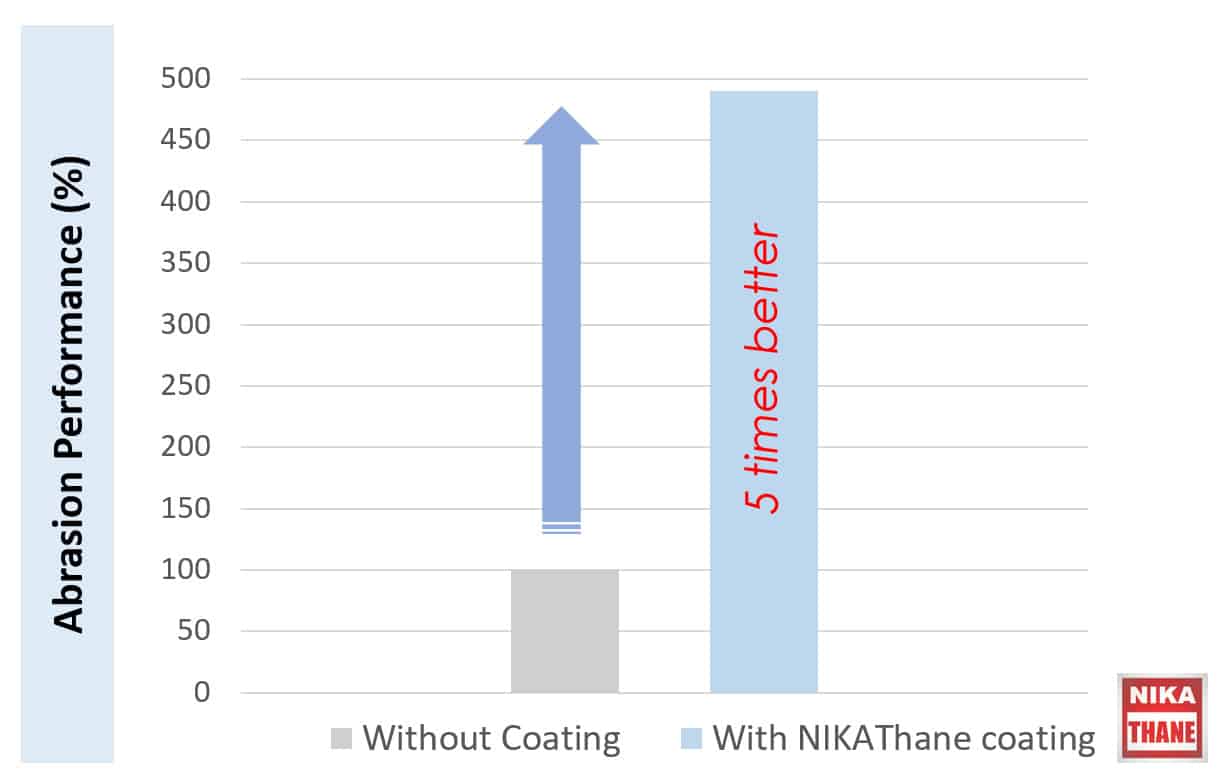

When abrasion is a service life limiting factor, our special NIKA-Thane Polyurethane based coating improves drastically the performance of the rope and the durability against abrasion. Test results have shown 5 times better durability of coated Siri® fibers when compared to commonly used HMPE fibers without coating protection.