Minimize the risk of mooring line failure. Maximize safety for your crew

The updated MEG4 represents the output of a multi-discipline working group representing members of various shipping trade organizations, mooring line manufacturers, shipyards, and OCIMF members. Before the MEG4 there was no industry guidance on condition-based monitoring of mooring lines and tails. The new MEG has strived to provide guidance and clarity on the condition-monitoring of mooring lines. Below is a list of some new terms that will be introduced in MEG4.

Ship Design Minimum Breaking Load – SDMBL. The minimum breaking load of new, dry mooring lines for which a ship’s mooring system is designed, to meet OCIMF standard environmental criteria restraint requirements. The SDMBL is the core parameter against which all the other components of a ship’s mooring system are sized and designed with defined tolerances.

Line Design Break Force – LDBF. LDBF is the minimum force that a new, dry, spliced mooring line will break at when tested according to appendix B. This is for all mooring lines and tail materials except those manufactured from nylon which is tested wet and spliced. This value is declared by the manufacturer on each line’s mooring line certificate (see appendix B) and is stated on a manufacturer’s line datasheet. As outlined in appendix B, when selecting lines, the LDBF of a line shall be 100%–105% of the SDMBL.

Tail Design Break Force – TDBF. TDBF is the minimum force that a new, dry, spliced mooring tail will break at when tested according to appendix B. This is for all mooring lines and tail materials except those manufactured from nylon which is tested wet and spliced. This value is declared by the manufacturer on each line’s mooring line certificate (see appendix B) and is stated on a manufacturer’s line datasheet. As outlined in appendix B, when selecting lines, the TDBF of a line shall be 125%–130% of the SDMBL. The TDBF for nylon mooring lines should be specified as break tested wet because nylon tails change strength characteristics once exposed to water.

Working Load Limit – WLL (instead SWL). The maximum load that a mooring line should be subjected to in operational service, calculated from the standard environmental criteria. The WLL is expressed as a percentage of ship design MBL and should be used as a limiting value in both ship design and operational mooring analyses. During operation, the WLL should not be exceeded.

Line Management Plan – LMP. LMP is used to manage the operation and retirement of mooring lines and tails. The LMP also documents the requirements, assumptions and evaluation methods used in determining the line retirement criteria. The LMP is specific to an operator, ship type, mooring line type and trade route.

Mooring System Management Plan – MSMP. The MSMP which will complement the ship’s SMS. Through a ‘goal-based’ approach core elements of the mooring system are identified, against which high level ‘goals’ are established supported by more detailed ‘functional requirements.

With the MEG3 standard the criteria were only:

New standards of inspection-monitoring:

i) Environmental criteria

ii) Other criteria

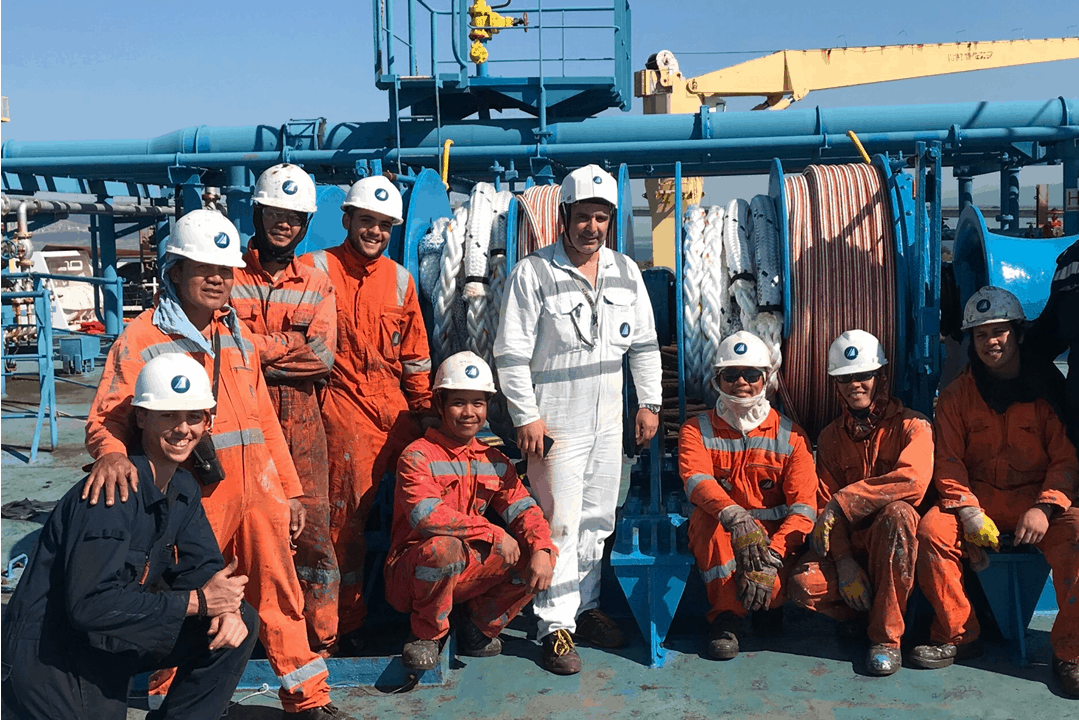

Support for optimal mooring line selection and LMP according to MEG4. The ropemaker experts will be assigned to your project and will work closely with your managers.

The support offered includes conference calls, on-site visits from the assigned sales account manager as well as from an expert Engineer.

Furthermore, we will follow up whenever changes in specifications or production schedules are applied, in order to fully serve your project’s specific requirements.

Training courses from ropemaker experts can train your crew and executives in safety, maintenance, inspection, and management of your mooring lines according to OCIMF MEG4, IMO & ISO/CI standards.

The training courses are designed to provide you with increased crew safety and improved management of your mooring ropes.

The training courses include instructional videos and presentations, easy-to-fill checklists for onboard procedures and online technical support.

Ropemakers must help you assess the condition of your mooring lines worldwide, at any time. Rope Technicians can perform onboard visual quality inspections and audit your mooring operation. After the inspection, you will receive a comprehensive official inspection report about the condition of your mooring lines and recommendations for your mooring operation.

Also monitoring software from makers of ropes can be used to track line usage & condition to reliably prevision the replacement of your mooring lines & tails according to MEG4. Last but not least makers of ropes must evaluate precisely the remaining operational life of your mooring lines. All testing will be done according to the latest OCIMF & ISO/CI standards. Your mooring lines & mooring tails must to replacement with strength not less 75% of SDMBL strength.

Subscribe to our newsletter

This website uses cookies to improve user experience. By using our website you consent to all cookies in accordance with our Cookie Policy.