With the continuous increase in shipping industry demands, worldwide trading vessels are operating in various climates, including extremely low ambient temperatures and hot climates.

KATRADIS MARINE ROPES INDUSTRY SA has developed the new LCP–Siri® S12 (with Vectran) Covered ropes, as one of the latest innovations in the field of high modulus synthetic fiber mooring lines. These ropes are ideal for worldwide trading vessels and comply with the latest guidelines of the shipping industry (MEG4, IMO, SOLAS Circulars).

LCP–Siri® S12’s construction is made from a 12-strand LCP load-bearing core (VECTRAN™ fibers by Kuraray) overbraided by a non-load-bearing protective cover.

The rope is processed with Katradis LSP (Linear Structural Preformation technology) to enhance mechanical properties such as abrasion resistance and tensile strength. VECTRAN™ is a high-performance multifilament yarn spun from a liquid crystal polymer. It offers a unique combination of properties for demanding applications.

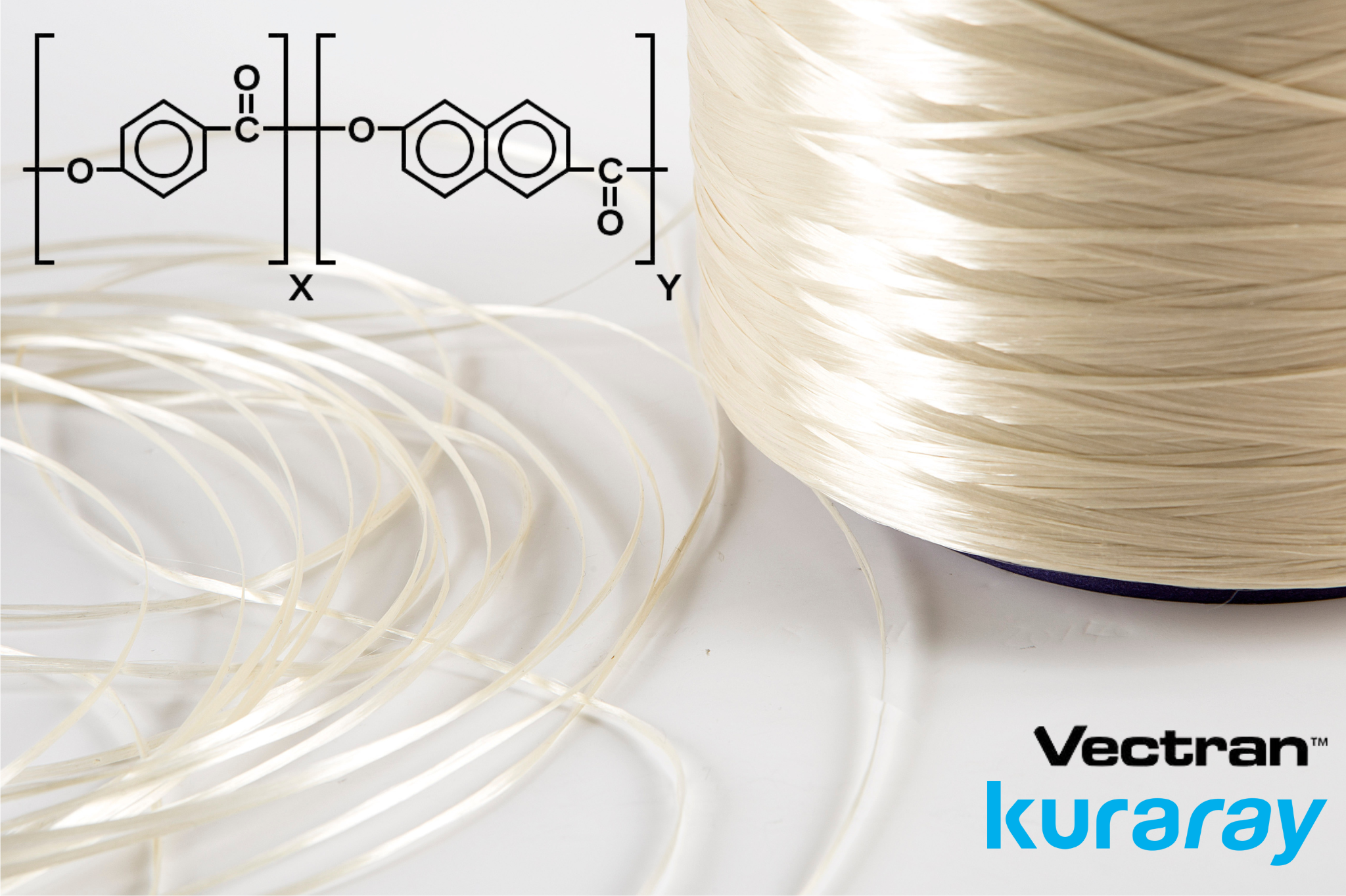

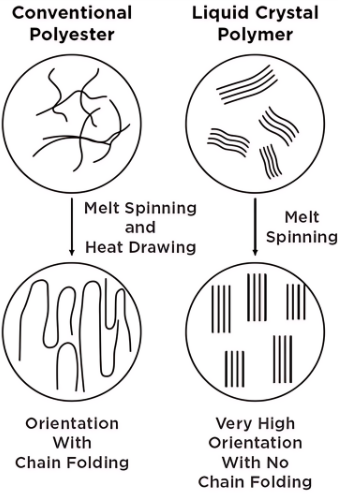

VECTRAN™ is a high modulus multifilament fiber developed by Kuraray, offering a unique combination of properties for demanding applications. It’s highly oriented structure is locked in directly during the melt spinning process, thanks to the molecular structure and crystalline nature of the starting polymer.

Currently, LCP-Siri S12 is the only commercially available mooring line in the world with a VECTRAN™ liquid crystal polymer core. This exclusivity is due to Katradis being the sole mooring line manufacturer partnered with Kuraray to develop and produce VECTRAN™ based mooring lines as of today. Kuraray, a leading global chemical company founded in 1926 in Kurashiki, Japan, has over half a century of experience in the maritime sector and is the world’s largest producer of thermotropic liquid crystal polymer fibers, with all VECTRAN™ mooring line fibers being produced in Japan.

| Fiber Properties | |||||

| Specific Gravity | Melting point | Tenacity | Elongation at break | Chemical resistance | UV Resistance |

| 1.40 | 330°C | > 30 gr/den | 4.5 % | Very Good | Very Good |

Find out LCP-Siri S12® Vectran™ COVERED

Key Benefits of VECTRAN™

Unlike other superfibers such as para-aramid and HMPE, VECTRAN™ is made from thermotropic Liquid Crystal Polymer (LCP), a type of polymer with stiff, rod-like molecules that align in both solid and molten states, creating a highly ordered structure. This alignment occurs during the melt spinning process, where the polymer is pushed through nozzles, aligning the molecules parallel to the fiber’s axis. This unique process results in fibers with exceptional tensile strength.

Unlike other superfibers such as para-aramid and HMPE, VECTRAN™ is made from thermotropic Liquid Crystal Polymer (LCP), a type of polymer with stiff, rod-like molecules that align in both solid and molten states, creating a highly ordered structure. This alignment occurs during the melt spinning process, where the polymer is pushed through nozzles, aligning the molecules parallel to the fiber’s axis. This unique process results in fibers with exceptional tensile strength.

VECTRAN™ is one of the strongest and lightest synthetic fibers commercially available today. Originally developed in the 1980s specifically for maritime applications, it emerged in response to the US Navy’s dissatisfaction with the performance of existing high-performance fibers (sometimes called superfibers) in saltwater environments. These fibers often suffered from poor abrasion resistance, absorbed water making them heavy and difficult to handle, and had a tendency to creep (become longer) over time.

VECTRAN™ was designed from the beginning to be the ideal maritime fiber:

• High Strength-to-Weight Ratio: It can withstand immense forces, crucial for securing large vessels, while its light weight simplifies handling and deployment.

• Hydrophobic: It repels water, avoiding the weight and performance issues associated with water absorption, and retains its strength in saltwater.

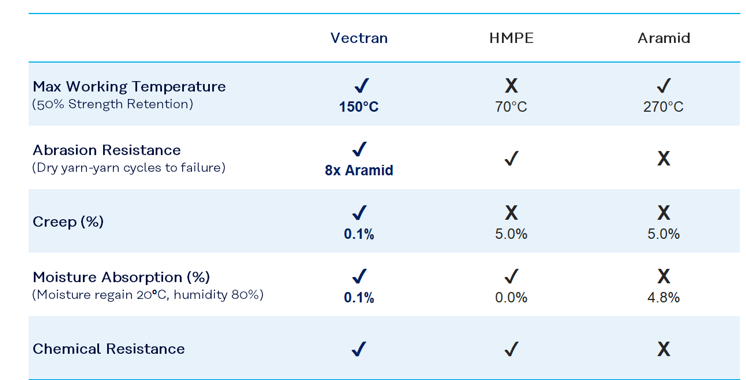

• Abrasion Resistance: It is ten times more resistant to wear and tear than para-aramid fibers, ensuring durability.

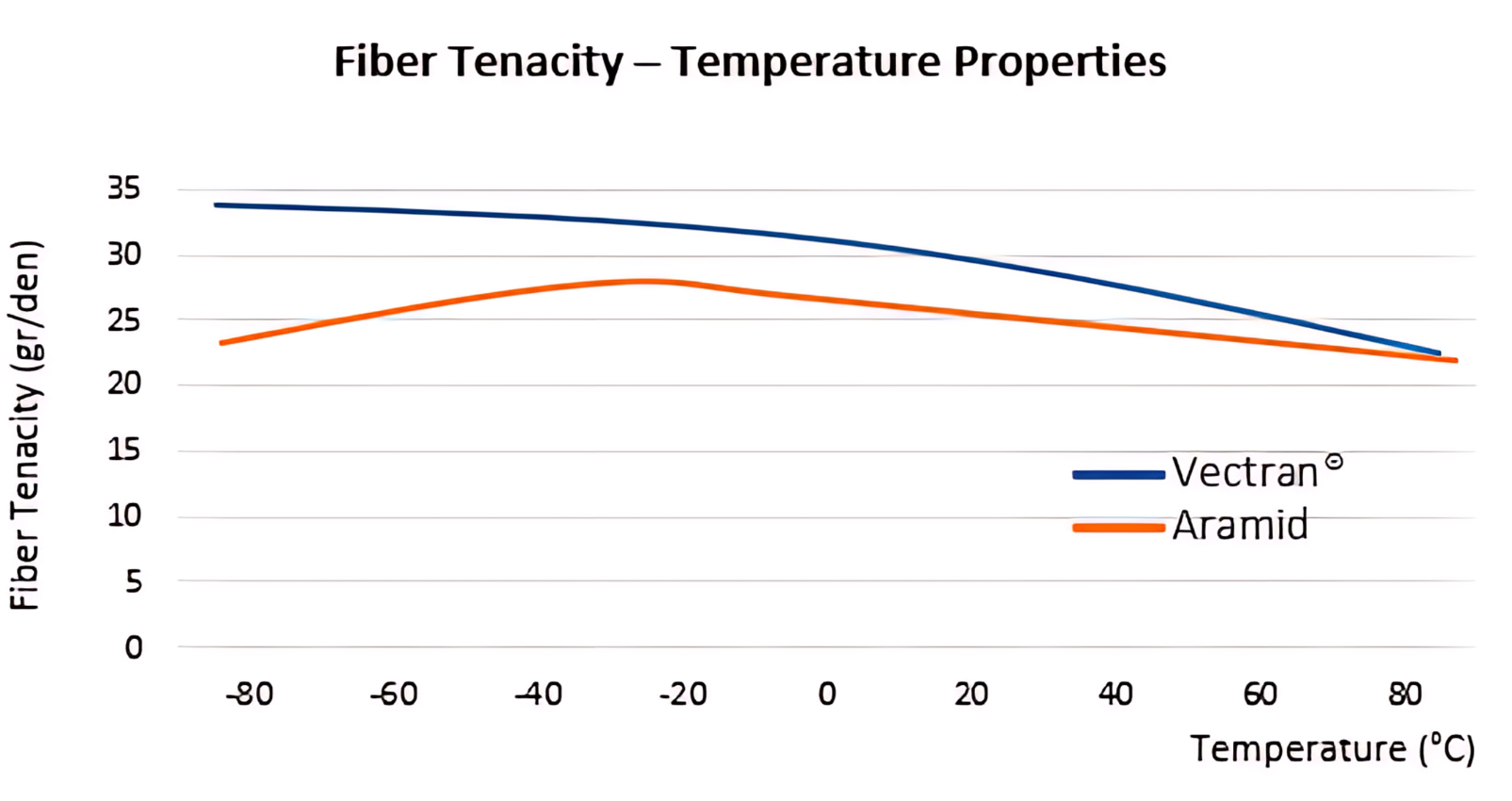

• Temperature Resistance: VECTRAN™ has three times the temperature resistance of HMPE, making it suitable for environments ranging from Arctic chill to the Persian Gulf’s heat.

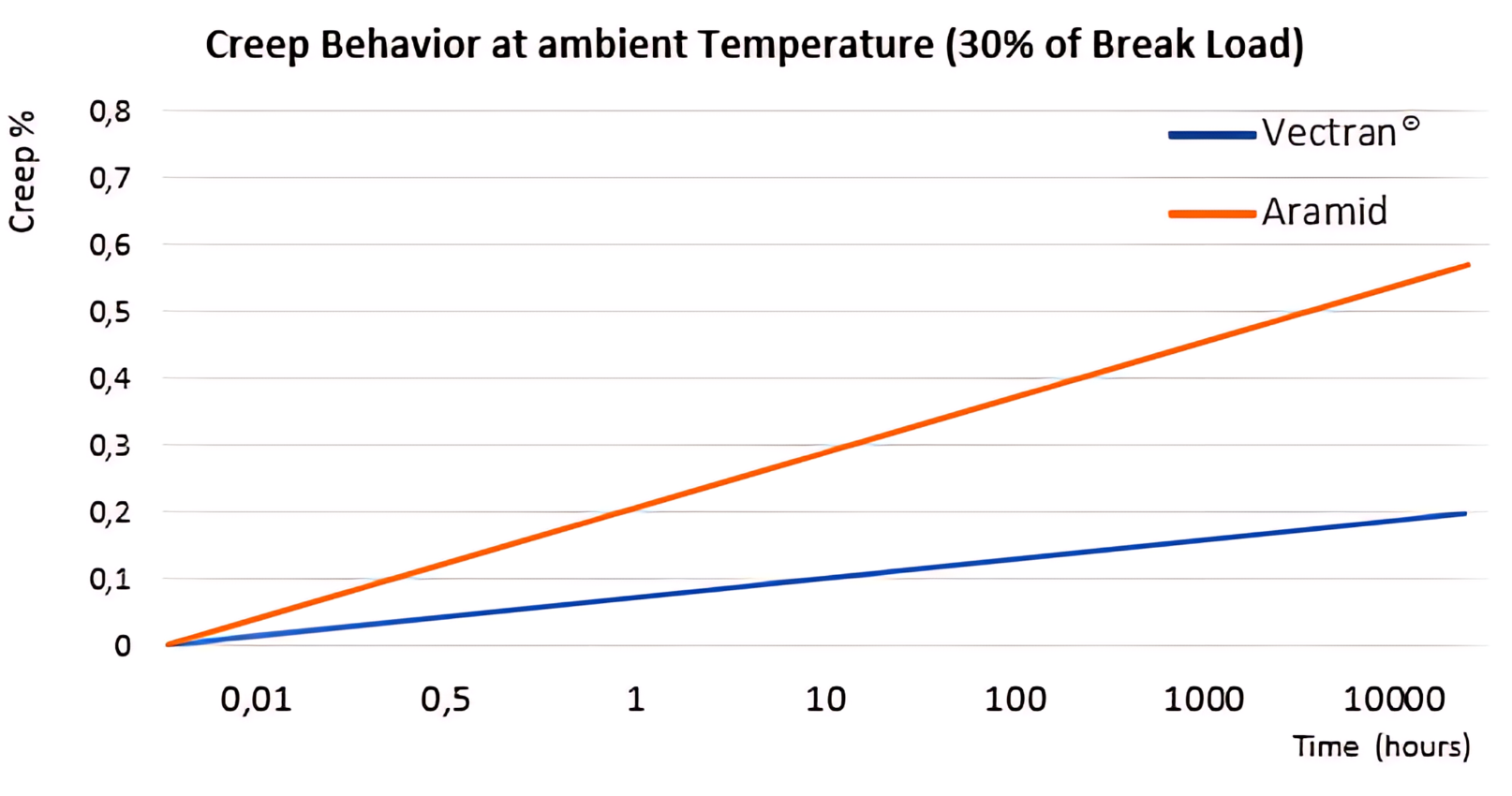

• Negligible Creep: Creep is the permanent elongation that occurs when fibers are subjected to a constant load, which can reduce the rope’s service life. VECTRAN™ has just 0.1% creep, the lowest among mooring line synthetic fibers, giving VECTRAN™-based mooring lines greater durability.

How VECTRAN™ Differs from Other Superfibers:

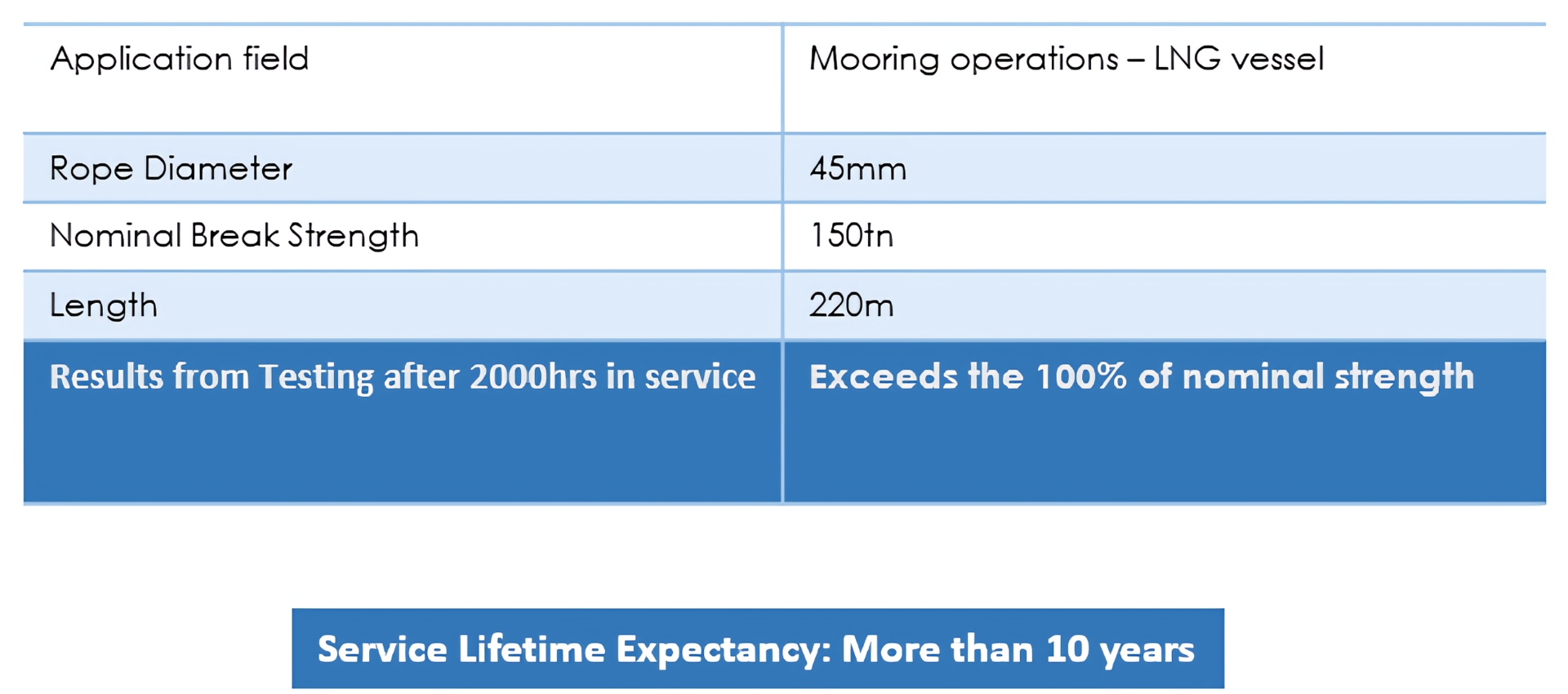

The one word that best describes VECTRAN™ is “consistency.” Whether in hot or cold, wet or dry conditions, it performs consistently. Remarkably, after 2000 hours of testing on an LNG tanker in adverse climates LCP-Siri S12’s VECTRAN™ core still retained 100% of its original strength with no visible signs of wear.

Monitoring the performance and condition of used LCP-Siri® S12 mooring ropes has shown that they have excellent residual strength. Samples from working mooring lines have been taken for in-house testing to evaluate the planned operational service lifetime.

LCP-Siri® ropes are designed to endure the demands of mooring operations for long term service life.

Upon internal visual inspection, the fiber core, after the removal of its protective jacket, shows no signs of damage or degradation.