As Cruise Vessels grow in size, complexity, and global reach, mooring lines must evolve to meet the increasing demands of port safety, handling efficiency, and long-term durability. At KATRADIS Marine Ropes, we are proud to introduce two cutting edge solutions designed specifically for the cruise industry:

🔹 SeaLite 24 – a mixed-fiber mooring rope offering shock absorption, floating capability, and versatility

🔹 SeaLite HP – a high modulus rope engineered for ultra-high strength, minimal elongation, and low snap-back risk

Both ropes are developed in-house at our manufacturing facilities, backed by over 88 years of marine engineering expertise, and fully compliant with international standards. Whether you’re managing Caribbean mega-ships or polar expedition liners, SeaLite 24 and SeaLite HP offer you confidence in every mooring operation.

With over 88 years of experience in the marine industry, KATRADIS continues to lead in rope engineering and mooring solutions. SeaLite 24 Rope is part of our rope series designed for the specific needs of the cruise sector.

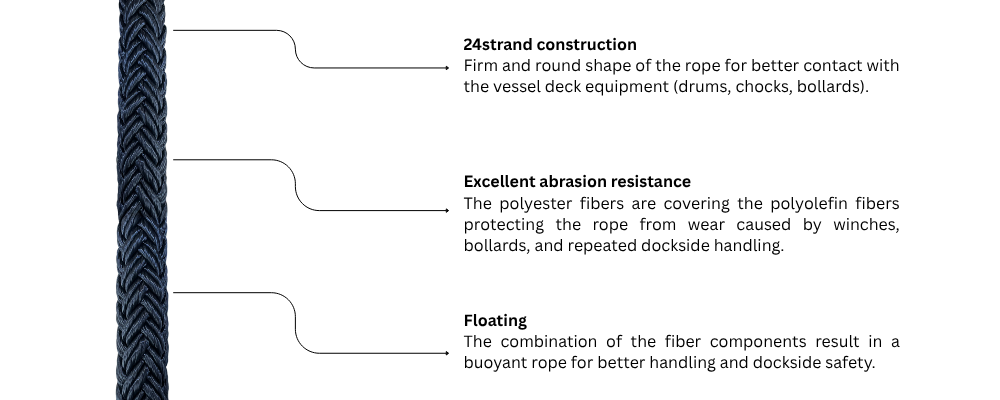

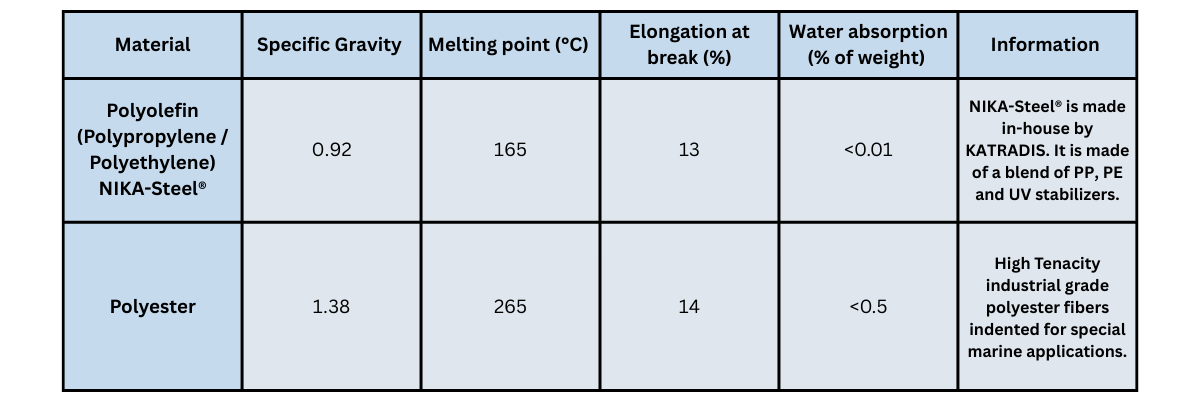

Engineered at KATRADIS in-house manufacturing facilities, SeaLite 24 mixed rope features a dual-fiber blend of high-tenacity polyester and polyolefin fibers, offering a unique combination of strength, floatability, and controlled elongation. This construction not only enhances rope handling and performance during port maneuvers but also ensures long-lasting resilience in the harsh marine environment.

The blended construction offers controlled elasticity, ideal for cruise ships that undergo varying tension loads during mooring. This helps to absorb dynamic energy from swell, wake, or wind without overloading the line.

Engineered for UV, saltwater, and abrasion resistance, SeaLite maintains its integrity across a range of environments—from sunny Mediterranean ports to Arctic expedition harbors ensuring consistency in safety and performance.

Explore Sealite 24 Rope

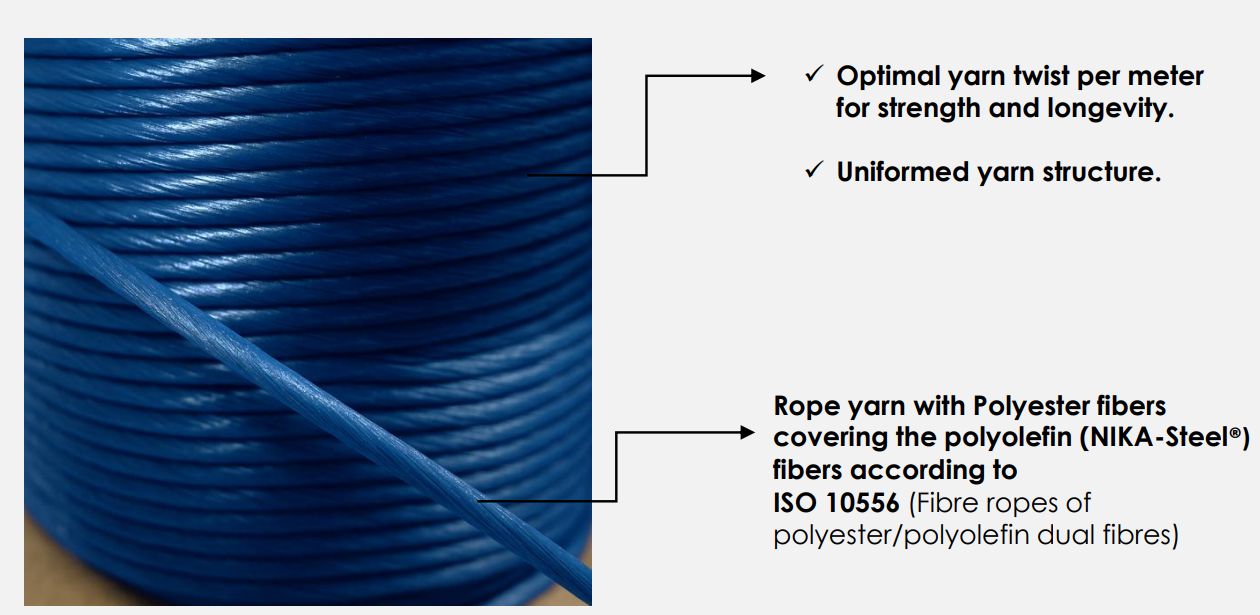

Yarn composition plays a critical role in the performance and durability of synthetic ropes. Proper twisting methods increase the yarn abrasion resistance, enhance energy absorption during dynamic loads, and extend the rope’s service life. This manufacturing process adheres to ISO 10556, which specifies the construction, testing, and performance characteristics of fiber ropes used in mooring applications.

Whether mooring a 120,000-tonne megaship in the Caribbean or an expedition vessel in the Arctic, SeaLite HP ropes offers the reliability and resilience that cruise operators need.

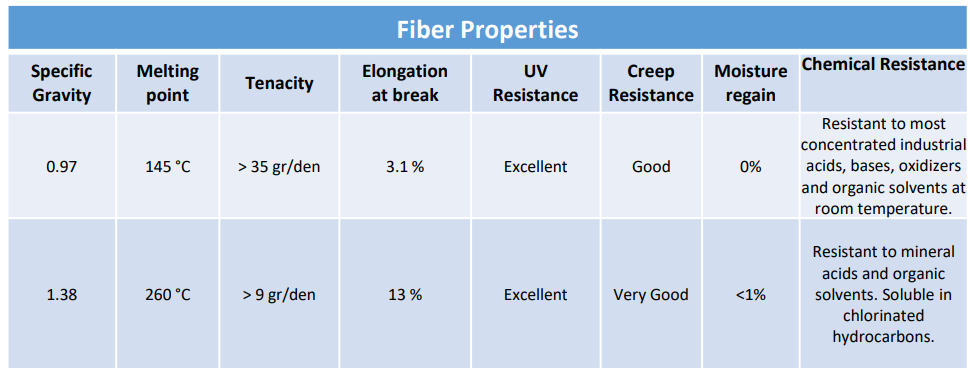

As the cruise industry grows in scale, the demands on mooring systems have never been greater. SeaLite HP mooring rope is the latest development of KATRADIS designed specifically to meet the operational and environmental requirements of today’s cruise vessels. SeaLite HP combines the mechanical properties of HMPE (High Modulus Polyethylene) fibers into a unique rope structure for the perfect balance between strength, durability and ease of handling. Designed with decades of maritime expertise, this rope ensures efficient port calls, passenger safety, and operational

excellence.

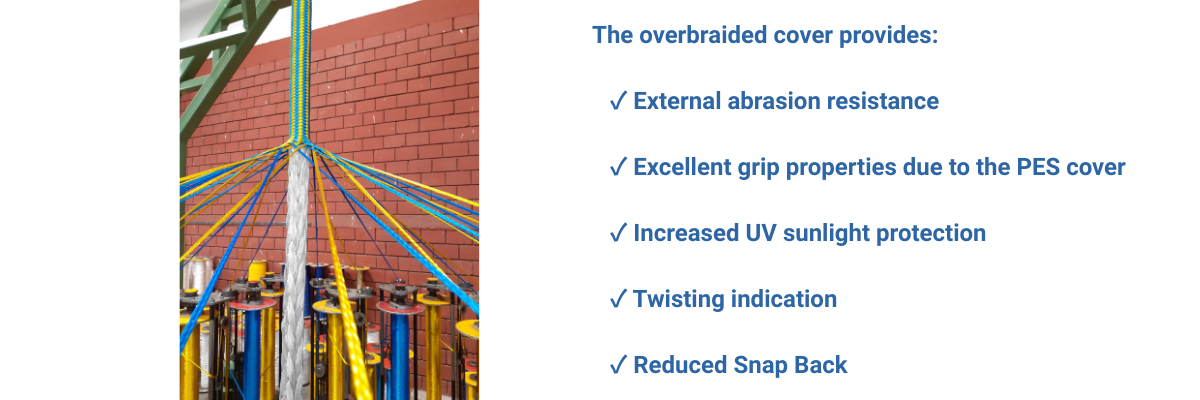

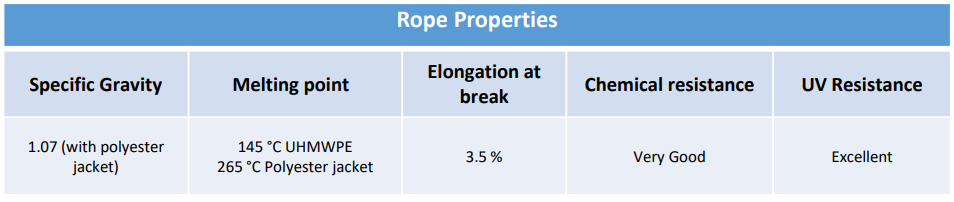

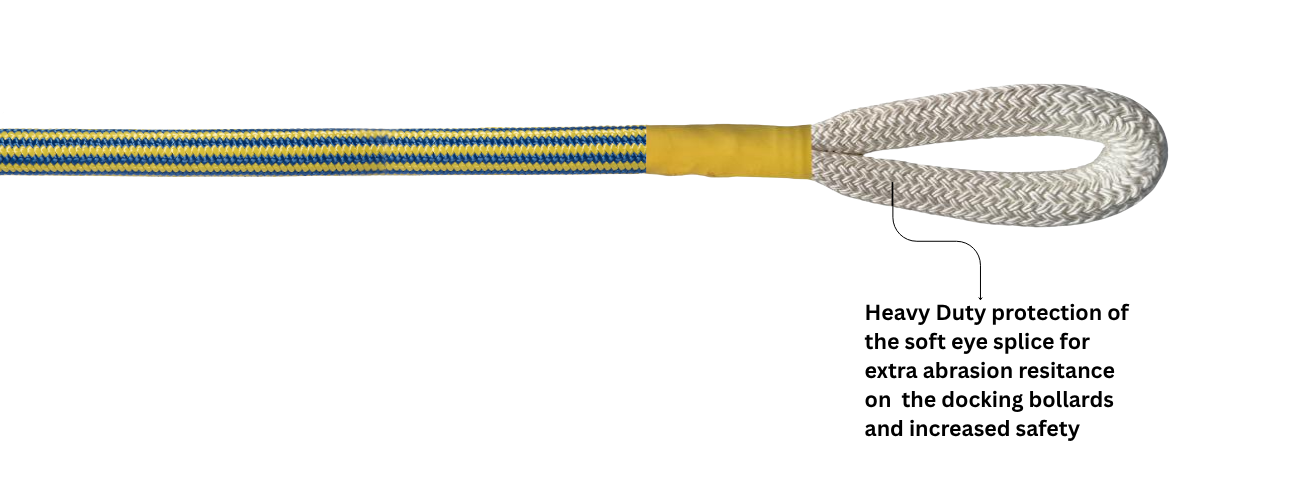

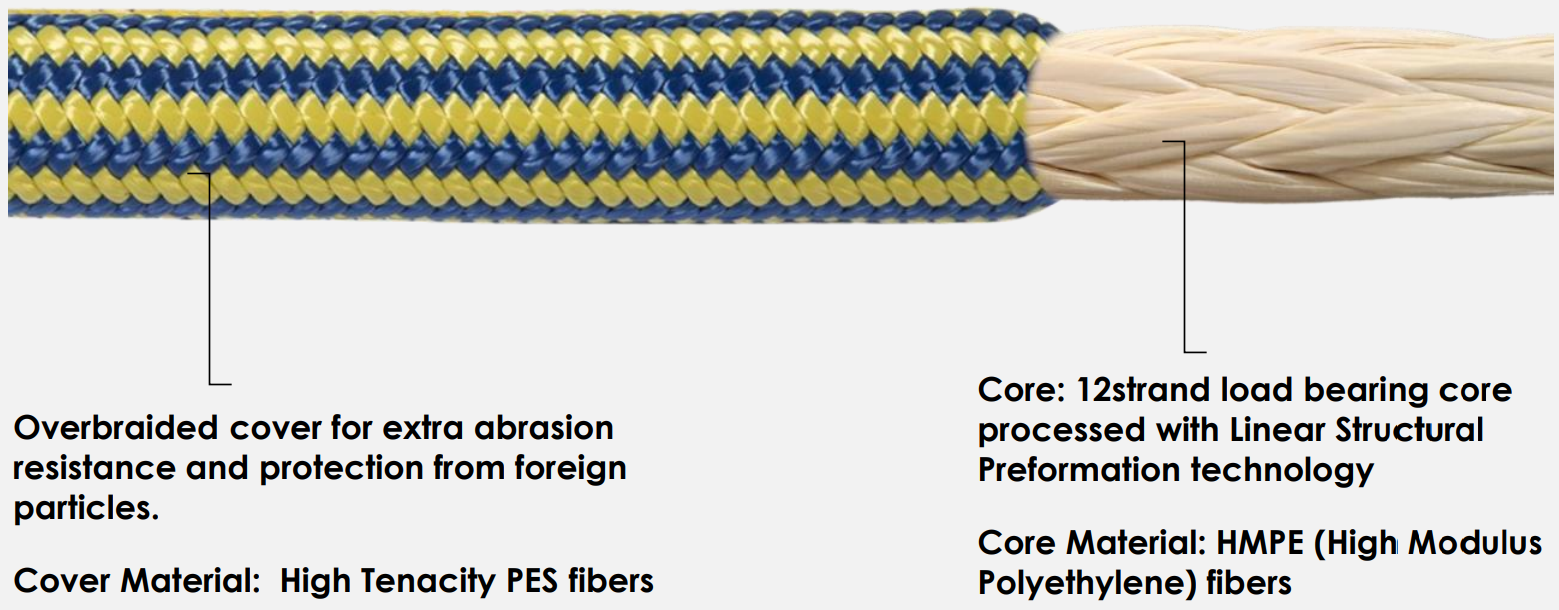

SeaLite HP mooring rope consists of a 12strand HMPE load bearing core overbraided by non-load bearing protective cover. This rope construction is firm, round and rotation resistant.

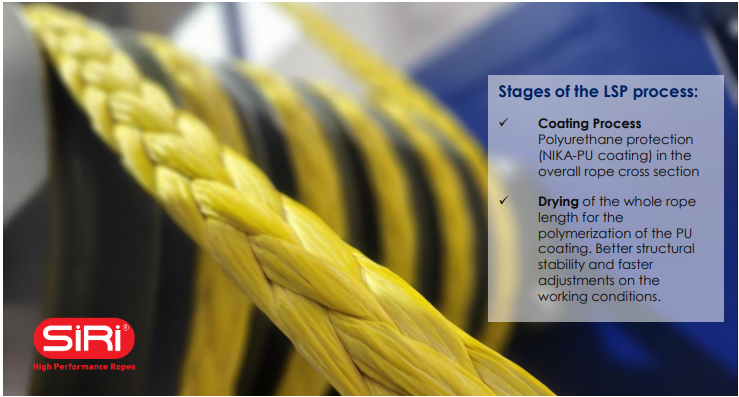

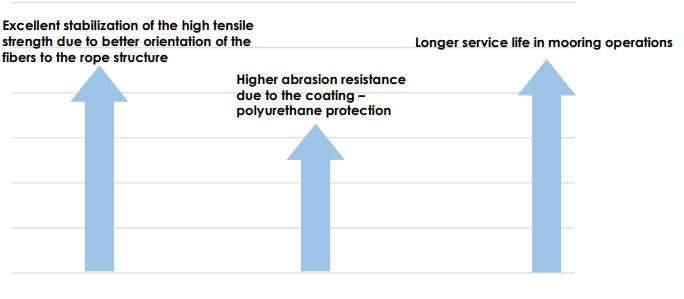

KATRADIS MARINE ROPES INDUSTRY SA has developed the Linear Structural Preformation (LSP), a two-step procedure integrated in the rope manufacturing process. Through LSP, the rope is processed with coating emulsion while tensioned and aligned under controlled linear load conditions. This drastically reduces initial constructional elongation and eliminates bedding-in issues that typically arise in the early cycles of rope use. For Cruise ships this translates into a rope that performs consistently from day one, with minimal readjustments required.

Designed in KATRADIS production facilities and manufactured according to ISO 10325 standard, ensuring full compliance with international specifications for fiber rope construction, testing, and performance.