Proper Wire Rope care is essential for ensuring safety, performance, and long-term value. Regular inspection and maintenance help prevent accidents and costly equipment failures by identifying wear, corrosion, or damage before they become critical issues. Proper care also significantly extends the operational lifespan of the rope, maximizing your investment and reducing the frequency of replacements. This leads to substantial cost savings over time while maintaining optimal efficiency. Moreover, adhering to recognized standards such as EN 12385, ISO 4309, and MEG4 ensures full compliance with industry regulations, protecting both personnel and operations.

In short terms the importance on a Proper Wire Rope Care is for:

- Safety: Prevents accidents and equipment failure

- Lifespan: Extends operational use

- Cost savings: Reduces replacements

- Compliance: EN 12385, ISO 4309, MEG4

Inspection Practices

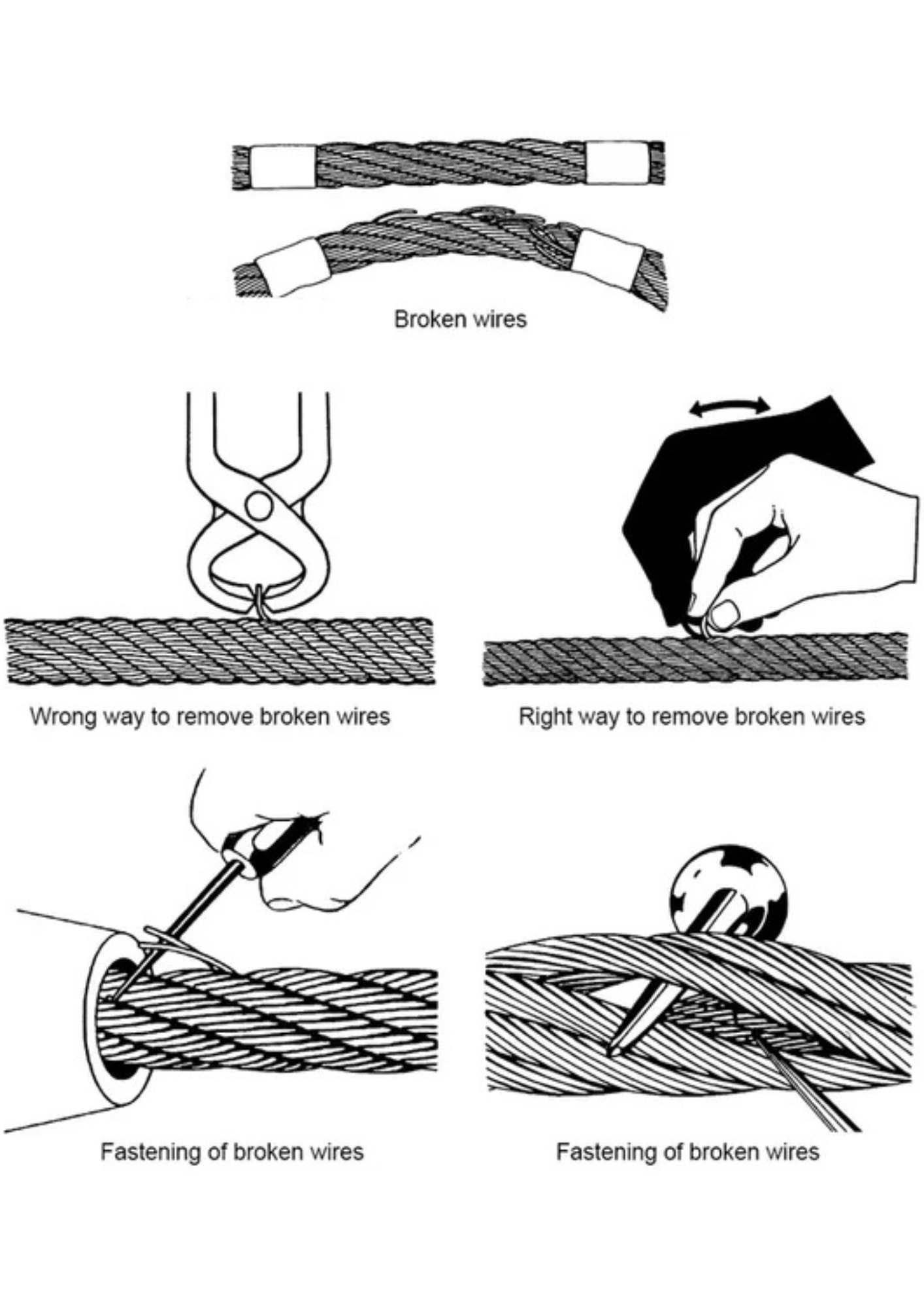

Any Wire Rope that has broken wires, deformed strands, variations in diameter or any change from its normal appearance must be considered for replacement. It is always better to replace a rope when there is any doubt concerning its condition or its ability to perform the required task. The cost of wire rope replacement is quite insignificant when considered in terms of human injuries,

Any Wire Rope that has broken wires, deformed strands, variations in diameter or any change from its normal appearance must be considered for replacement. It is always better to replace a rope when there is any doubt concerning its condition or its ability to perform the required task. The cost of wire rope replacement is quite insignificant when considered in terms of human injuries,

the cost of down time, or the cost of replacing broken structures.

Wire rope inspection includes examination of basic items such as:

- Rope diameter differentiations

- Rope lay

- External wear

- Internal wear

- Peening

- Scrubbing

- Corrosion

- Broken wires

Regular Wire Rope inspections are essential to maintaining safety and performance throughout its service life. Visual checks should be carried out before use, during operation, after use, and periodically as part of a scheduled maintenance routine. The rope must be replaced if the number of broken wires exceeds the allowable limits within a 6d or 30d length, or if visible damage such as birdcaging, doglegs, popped core, or other deformations is detected. In cases of complete strand failure, the rope must be discarded immediately. For detailed discard criteria and inspection guidelines, always refer to ISO 4309 and MEG4 standards, or contact our company for expert guidance and support.

Procedures for Testing of used Wire Ropes

In order to extract accurate and reliable results, the Client who requests the forensic report, should provide to KATRADIS the certificate of the subject wire rope and if available the total mooring hours and photos from the wire rope on-board.

The Wire rope should be inspected and results logged for any local damages that can be identified visually as per the supplie’s guidelines for visual inspection.

Destructive test for used ropes (MEG4) at KATRADIS facilities

For determining the residual strength of the wire, a destructive (break) test can be performed. This test can never be considered as a quality / usage level for the rest wire rope length from wich the specific specimen was cut.

Any

Any