When it comes to vessel and crew safety during mooring operation, the quality and condition of mooring ropes play a critical role. The safety level that mooring lines provide depends not only on their initial strength, but also on how they withstand the challenges of environmental conditions and sunlight exposure. That’s why KATRADIS mooring ropes are engineered with appropriate UV resistance which results in long-term performance and reliability.

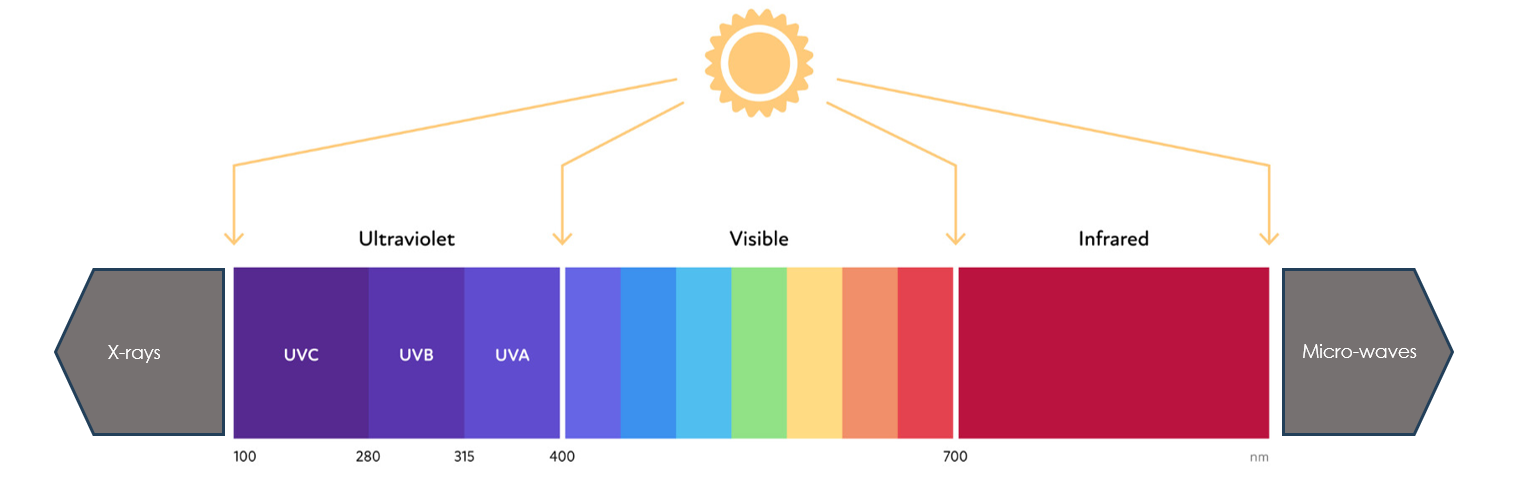

The sunlight that reaches Earth’s surface after passing through the atmosphere, contains the visible light and parts of the UV and infrared wavelengths. This spectrum also comes in contact with the synthetic mooring ropes when exposed to sunlight and can react with the ropes’ polymer material.

Ultraviolet (UV) radiation is about 3% of the total sunlight, but it’s a critical factor of damage to synthetic ropes through a process known as UV degradation. The extent of degradation depends on several key factors, such as rope material, exposure duration, sunlight intensity, protective treatments on the rope and maintenance after operation.

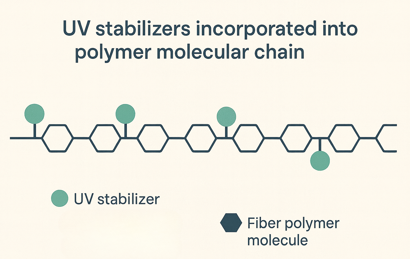

Protecting the synthetic ropes, mostly Polyolefin, Polyester and Nylon from UV degradation may include the usage of UV stabilizers which are integrated into the fiber molecular structure. The UV stabilizer molecules are connected with the main polymer chains in the fiber structure and absorb selectively only the harmful UV sunlight.

The UV stabilizer molecules connected

with the main polymer chains in the rope fiber.

When the rope is exposed to the sunlight, the UV stabilizer absorbs the harmful sunlight and prevents the photo-oxidation effect. Once stabilized, the UV degradation process will be considerably slowed. Especially if combined with proper maintenance, a UV stabilized rope has significantly longer lifetime.

![]()

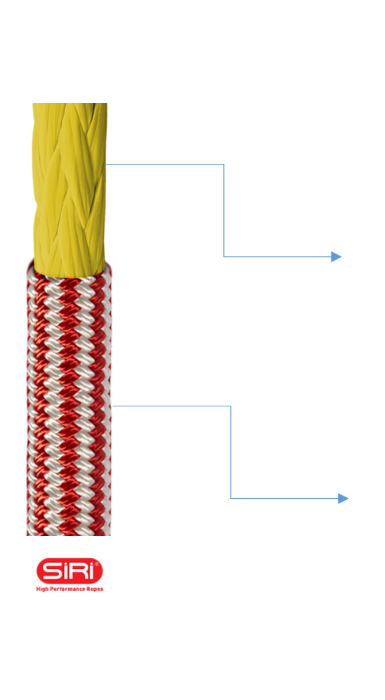

For Katradis Siri High Performance ropes (HMPE or LCP), where the integration of UV stabilizers is not feasible into the molecular chain, the UV degradation can be addressed with the use of special coatings and covered constructions that protect the load-bearing member.

Load-bearing member

Protected with UV resistant polyurethane coating. Katradis has developed the special LSP (Linear Structural Preformation) process where the coating is applied in the whole rope cross section.

Externally braided cover

Totally absorbs the solar rays and prevents from entering the internal rope structure. The cover is made from UV stabilized material for maximizing the UV protection.

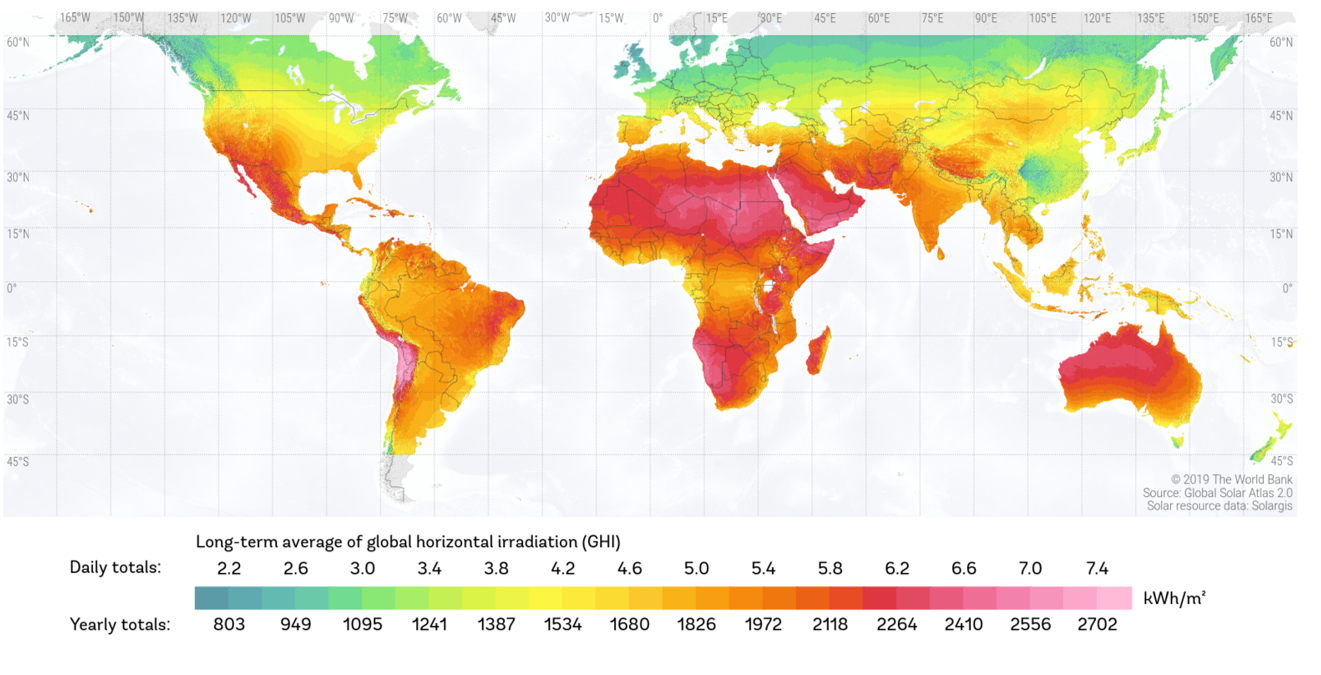

This map represents the average amount of solar energy received per square meter on a horizontal surface worldwide.

Low Irradiance (Green Zones – 800–1200 kWh/m²/year) Limited solar energy potential. For materials: low UV exposure → minimal photodegradation of synthetic ropes.

Moderate Irradiance (Yellow to Light Orange – 1200–1700 kWh/m²/year) Moderate UV degradation risk for synthetic materials. Protective UV stabilizers recommended for ropes.

High Irradiance (Orange – 1700–2100 kWh/m²/year) Strong UV impact → noticeable surface fading and strength loss in unprotected synthetic ropes. Marine and industrial applications in these areas must use UV-stabilized materials.

Very High Irradiance (Deep Red – 2100–2400 kWh/m²/year) Maximum UV degradation rate. Synthetic ropes (especially PP or PE) degrade quickly without UV stabilizers — surface embrittlement can occur in months.

Extreme Irradiance (Pink to Magenta – 2400–2700 kWh/m²/year) Severe UV damage potential. Materials must use UV stabilizers or surface coatings. Rope inspection frequency should be increased – shade storage is essential.

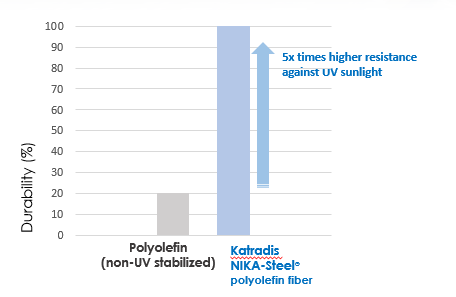

Simulation testing of UV stabilized fibers compared to non-UV stabilized fibers shows significant difference in durability over exposure time. Katradis mixed ropes are made of 100% UV-stabilized fibers to protect from sunlight and extent the service life in mooring operations.

To preserve the performance and extend the service life of synthetic mooring ropes, proper storage is essential especially when it comes to avoiding UV damage. Ropes should be stored in a clean, well-ventilated, and dry environment, away from direct sunlight and high temperatures. Long-term UV exposure can lead to photo-degradation, reducing the rope’s mechanical properties over time.

Avoid placing ropes near heat sources, acidic or alkaline environments (e.g., sulfuric acid), or areas with chemical contaminants, as these can accelerate degradation. For optimal shelf-life of up to 5 years, keep ropes in their original packaging and off the ground, using appropriate racks or drums. Once deployed or unpacked, the shelf-life tracking stops, and the operational service life begins.