Offshore operations demand equipment that performs reliably under extreme loads, harsh environmental conditions, and long service cycles. Rope selection is therefore a critical factor affecting safety, efficiency, and total cost of ownership. Katradis Siri high modulus ropes are engineered specifically to meet these challenges, offering a combination of strength, durability, and manufacturing flexibility that makes them ideally suited for demanding offshore applications.

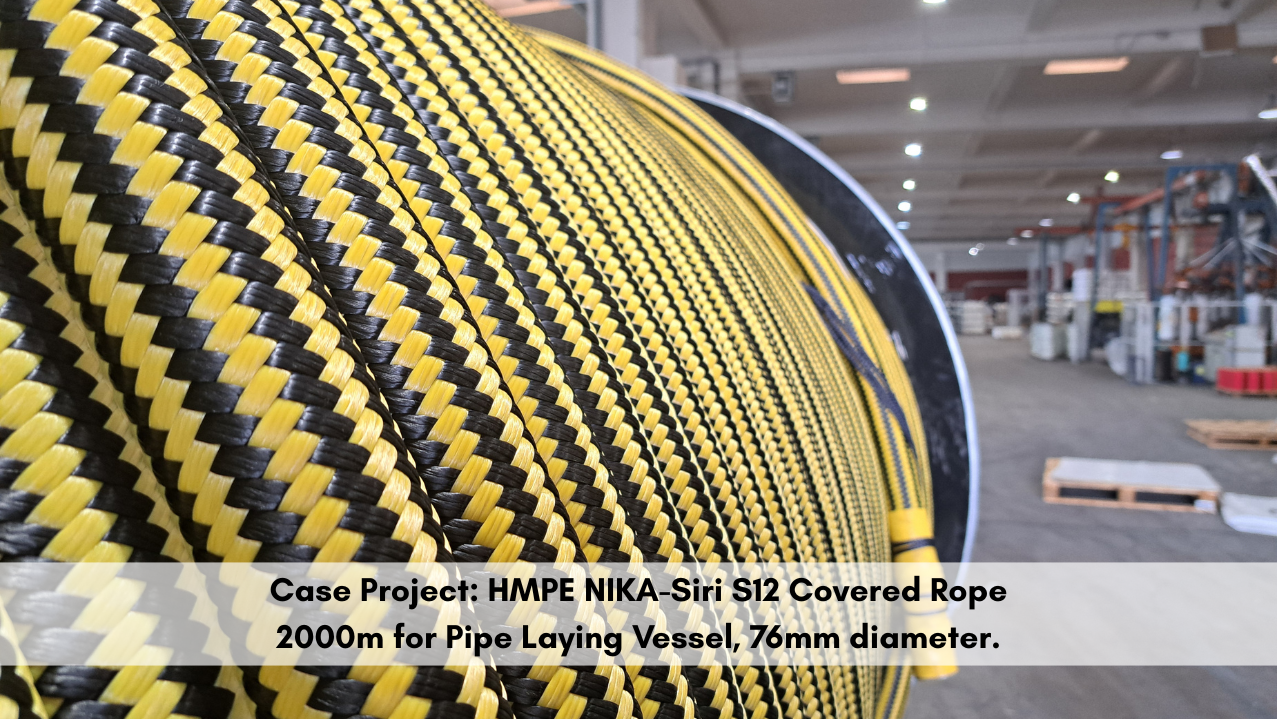

Anchoring operations for offshore vessels represent one of the most demanding applications for marine ropes. Offshore units such as anchor handling tug supply vessels (AHTS), offshore support vessels (OSVs) and pipe laying vessels operate in extreme and highly variable environments which require rope durability for the safety of operation.

Ropes are under constant loading and unloading conditions when controlling the anchoring equipment and the resistant against tension-tension fatigue is essential.

Siri® High Performance Ropes are made with the best manufacturing practices and demonstrate exceptional tensile strength combined with high durability.

Key Benefits:

The manufacture of synthetic ropes begins with selecting the right raw materials. Siri® high modulus fibers exhibit high strength and durability in marine applications, ideal for the replacement of steel wires with lighter ropes.

The fibers consist of extremely long molecular chains in high crystallinity structure. The molecular chains are highly linear and oriented in the fiber axis, resulting in exceptional mechanical properties compared to conventional materials that are used for marine ropes. KATRADIS emphasizes in the proper selection of raw material fibers that are used in the manufacturing of synthetic ropes, though strict quality control procedures and specialized laboratory.

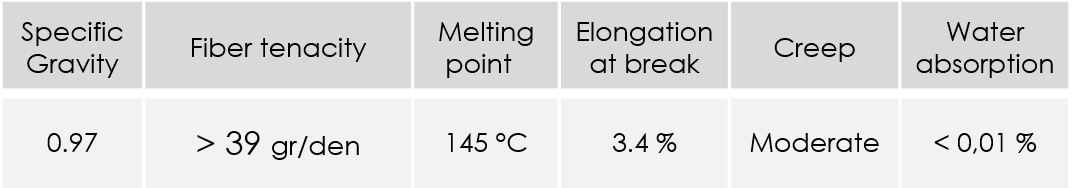

Siri HMPE (High Modulus Polyethylene) fibers exhibit high strength and lightweight characteristics.

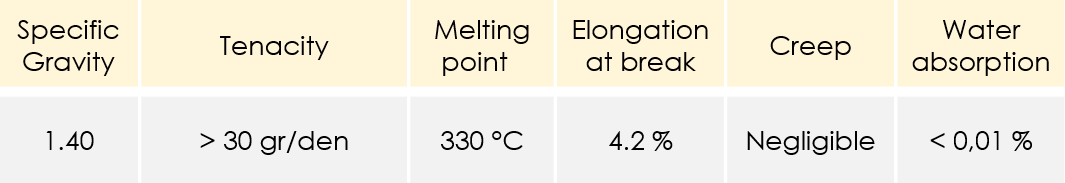

Supplied by Kuraray, VectranTM fibers are the first spun from liquid crystal polymer (LCP) and exhibit inherent advantages such as:

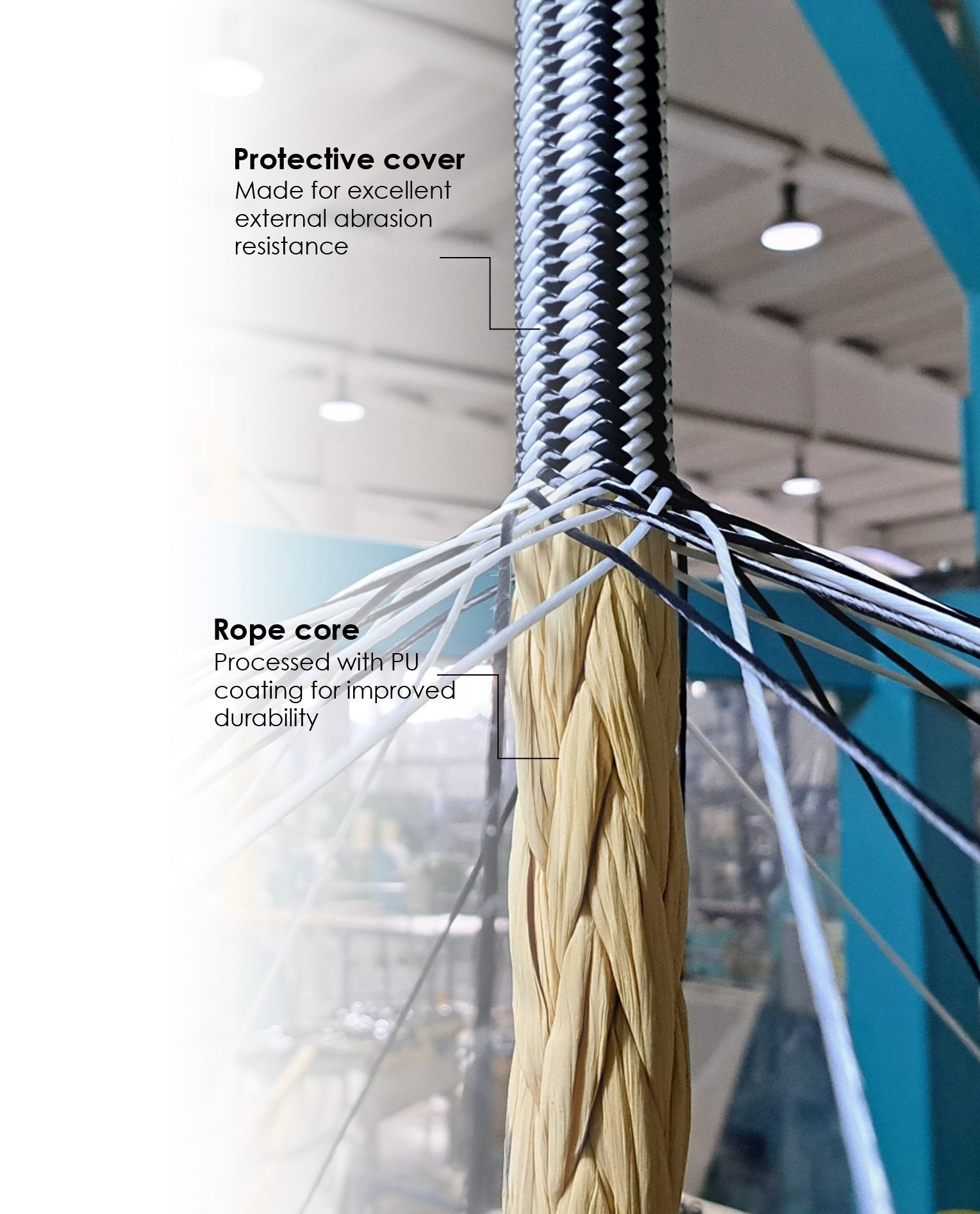

The special rope construction for offshore applications includes a load-bearing core overbraided by non-load bearing cover. The result is a round shaped, highly wear resistant rope for improved performance and ease of handling. Furthermore, KATRADIS has developed the LSP (Linear Structural Preformation) process for the increase of the rope lifetime. During this stage, the rope undergoes into Polyurethane (PU) coating the whole cross section, which results in robust structure and high abrasion resistance.

Features:

Offshore projects often require long length deployment of mooring ropes. This is necessary to ensure that the vessel remains stable and is not affected by the movement of the waves. Having an extended capacity, we manufacture a wide range of braided continuous lengths which can cover the most demanding requirements.

Proper installation is critical to the performance, safety, and longevity of high-performance ropes. KATRADIS offers expert installation supervision services to ensure that all ropes are installed correctly,

efficiently, and in full compliance with international standards and best practices.

Our experienced technical team provides on-site supervision during the installation of mooring, towing, lifting, and offshore ropes, supporting shipowners, shipyards, and operators at every stage of the process. From initial setup to final tensioning, we ensure that the rope is handled, installed, and terminated correctly, minimizing the risk of premature wear, damage, or operational failure.

Added Value for Your Operations

With KATRADIS installation supervision, you benefit from:

Maximum rope performance and service life

Increased operational safety

Reduced downtime and maintenance costs

Assurance that the installation meets both operational and regulatory requirements

KATRADIS combines decades of rope manufacturing expertise with hands-on technical support, ensuring that every installation delivers reliability, safety, and long-term performance in the most demanding marine and offshore environments.