Corrosion is one of the most persistent threats to sea infrastructure, driven by electrochemical reactions in aggressive seawater environments.

At KATRADIS S.A., we specialize in the development and production of high-performance sacrificial anodes for cathodic protection systems,

engineered to safeguard vessels, offshore platforms, and submerged structures.

Our NIKA® anodes are Lloyd’s Register Type Approved, manufactured under strict quality controls,

and optimized for long-term corrosion resistance, environmental compliance, and cost-effective lifecycle performance.

Cathodic protection is an electrochemical technique used to mitigate corrosion in metallic structures exposed to seawater.

By connecting a more anodic (less noble) metal to the protected structure, a galvanic cell is created.

The sacrificial anode corrodes in place of the structural metal, maintaining the integrity of hulls, rudders, tanks, and underwater appendages.

KATRADIS’ NIKA® sacrificial anodes are available in aluminum and cadmium-free zinc compositions:

| Material | Anode Potential (mV) | Capacity (Ah/kg) | Environment |

| Aluminum | -1100 | 2700 | Saltwater, cold climates |

| Zinc | -1050 | 780 | Brackish or mixed salinity |

Aluminum anodes offer high output and low weight, while zinc anodes ensure consistent protection in mixed salinity zones.

Our sacrificial anodes are Type Approved by Lloyd’s Register for:

This certification confirms compliance with international maritime standards and underscores KATRADIS’ reliability in global marine protection.

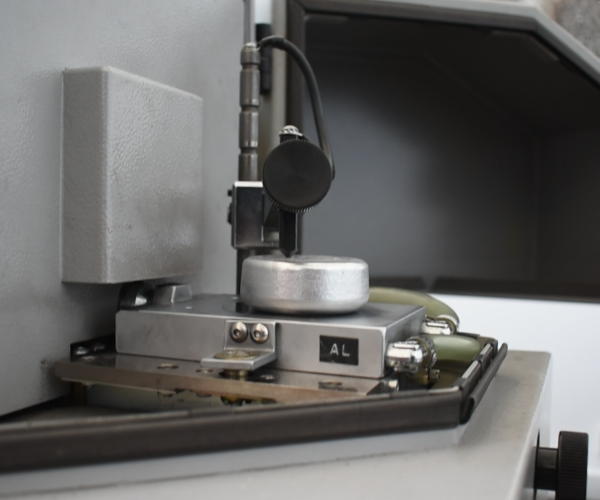

KATRADIS manufactures all NIKA® anodes in certified facilities in Greece, using:

Our cadmium-free and recyclable designs fully align with international marine environmental directives.

To ensure optimal Cathodic protection performance:

Maintenance intervals typically range from 1–2 years in saltwater to 3–5 years in brackish water, depending on operational conditions and structure type.

NIKA® anodes are utilized in a range of marine and offshore sectors, including:

Our Cathodic protection solutions are also integrated with protective coatings and epoxy systems to deliver a comprehensive multi-layered corrosion protection strategy.

With a legacy back to 1936, KATRADIS S.A. continues to set benchmarks in marine corrosion protection. Through certified engineering, advanced metallurgy, and sustainable production, we deliver sacrificial anode solutions that ensure asset longevity, safety, and environmental compliance.