All rights reserved -

Privacy Policy

Why similar-looking mooring ropes are not the same

When evaluating similar mooring ropes there are several parameters that are taken into consideration ranging from, weight, length, diameter, material, projected operational usage, vessel type, breaking strength, hardware, deck equipment, winch-type and naturally price.

However, there are two crucial aspects that are often overlooked. These important factors relate to the actual science and craft of manufacturing mooring ropes. These significantly impact not only the strength of mooring ropes but their performance over time. The first is:

Even in the case of High Modulus ropes which are made out of the same material, such as High Modulus PolyEthylene (HMPE) and Liquid Crystal Polymer (LCP), the actual manufacturing process is of huge importance to the rope performance in mooring operations.

Technologically advanced equipment, the twisting process, the coating procedures and the lay length construction of a rope have a significant impact on durability, abrasion and fatigue resistance. Short braiding lay lengths improve the performance of a rope when compared to longer braiding lay lengths.

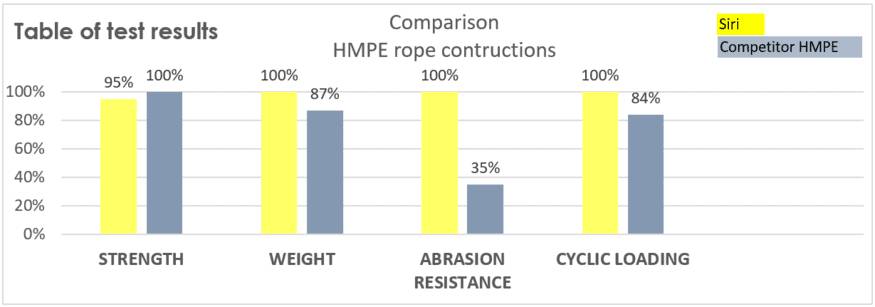

A series of comparative tests between our Siri rope with short braiding lay lengths and other HMPE ropes with longer braiding lay lengths have consistently delivered better long term results. Longer braiding lay lengths may result in rope structure with initially slightly higher break strength and lower weight but reduced performance in terms of abrasion resistance and cyclic loading. Taking into account a rope with one of the highest break strengths, Siri Ropes with shorter braiding lay length will last longer in mooring operations and are safer to use due to better abrasion and fatigue resistance.

Siri® manufacturing practice: Short braiding laylengths

Competitive Manufacturing practice: Long braiding laylengths

Consistency of fiber size and strength is important in the manufacturing of mooring ropes. Consistency enables the even distribution of force resulting in uniformity and increased rope strength compared to ropes made with uneven size fibers.

Even size fibers

Uneven size fibers

Even Vs Uneven size fibers mooring ropes life expectancy test results:

Even Fibers

Uneven Fibers

Katradis is a specialised manufacturer of mooring ropes serving the needs of the marine industry since 1936. With a unique tradition and uncompromising focus in the crafting of mooring ropes, we use the latest high-performance fibres in our products that are available via our international network in over 35 ports across the globe.

Commitment to reliability and quality

With a range of products from mooring ropes to sacrificial anodes, chains, anchors ship deck and port infrastructure equipment, we aim provide safety for the marine industry through the transfer of knowledge and quality products.

8.158 Vessels around the world trust Katradis products.

This website uses cookies to improve user experience. By using our website you consent to all cookies in accordance with our Cookie Policy.